crane jib

| Feature:Jib Crane,Tower Crane | Condition:New | Application:construction for tall building | Rated Loading Capacity:6t |

| Rated Lifting Moment:630KN.M | Max. Lifting Load:6t | Max. Lifting Height:151m | Span:56m |

| Place of Origin:Shandong China (Mainland) | Brand Name:Yongli | Model Number:TC5610 | Certification:ISO9001,CE |

| Standard section:1.6*1.6*2.8m |

1.High quality

Raw material is the foundation of produce and the first hurdle to guarantee quality Yongli tower crane bulk purchase steel directly form big steel factories like baogang,improve the safety of product.

2.Electrical mechanism

Select and use France Schneider contactor , broken phase and phase sequence protection and complete protection for motor overhead ,this can guarantee electrical mechanism run normally and safely.

3.Hoist mechanism

Brake wheel adopts cast steel materials,surface quenching and external circular,control the beating degree strictly .at the same time ,also carrying on balance tests .each hoisting mechanism is carrying on no-load ,static load ,dynamic load and so on,guarantee the reliability ,safety and durableness.

4.Derricking mechanism

Derricking mechanism with free maintenace planetary reducer and cone brake motor ,is well-knit in structure,stable and powerful in trolley ,high endurance and low failure rate.

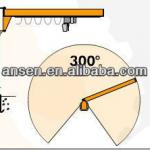

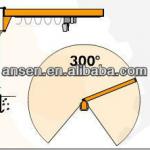

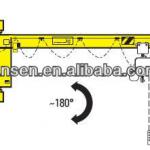

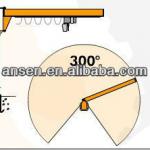

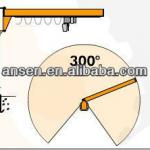

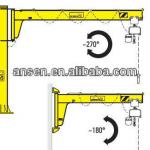

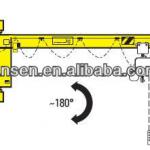

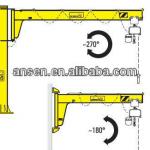

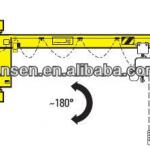

5.Slewing mechanism

Slewing motor adopts winding motor and hydraulic transmission.slewing is stable and powering.

6.Operation device

Cabin with humanized design,is convenient and comfortable,facilitate for safe driving.

7.Robot automatic welding system

This system is reliable in the performance ,with high work efficiency and high automatic degree .The welding quality of main load structure has reach advanced internationl degree in the same industry.

Turntable adops robot automatic welding ,make perfection more perfect and guarantee the quality of every product;mast section of construction elevator adopt tooling pssitioning and robot welding .It is not only guaratee the interchangeability of mast section and precision of rack positioning ,but as well make the welding more reliable and durable.

8.Automatic impeller blasting and spraying assembly line

Yongli company adopt the word first-class automatic spraying assembly line .The large structure parts are dealt with impeller blasting before sparaying .That remove steel surface oxides and welding apatters effectively ,eliminates the internal stress producing in welding process ,increases the parts’ anti-figure strength and steel surface service life of the product .Maxmizes efficiency and saves energy.

9.6M×12M CNC plasma cutting machine

Plasma cutting machine carries on cutting sheet material,not only quick cutting speed ,but also smooth cutting surface ,and small thermal deformation.

10.Safty protection

Safety protection devices are complete ,improving the safety .Weight limiters introduce the advanced pull-ring structure form abroad ,moments of force adopt bow-board mechanical type,and can adapt to severe wild environment .those make sure tower crane limiter sensitive and reliable,and avoid accidents of nonstandard use.

Technology parameters about QTZ5610

Tower crane TC5610 | ||||

Item | Unit | Fall | ||

| α=2 | α=4 | |||

Rated load moment | kn.m | 630 | ||

Max.load | T | 2 | 4 | |

Radius | M | 3~56 | ||

Tip max. load | t | 1.002 | 0.983 | |

Hoisting height | Independent | M | 41 | |

| Attached | 151 | 60 | ||

Trolley speed | M/min | 45/22 | ||

Hoisting speed | 0.4 | |||

Slew speed | R/min | 0.6 | ||

Outer size of the whole crane | chasis | m | 4.6*4.6 | |

| Standard section | 1.832*1.835*2.5 | |||

| Height of crane(independent) | 42.23 | |||

Weight of crane | Weight of independent structure | t | 31.15 | |

| Counterweight | t | 14.2 | ||

other | Motor capacity | kw | 34.6 | |

Top allowable wind speed | M/s | Operating≤20 | ||

Hoisting≤12 | ||||

| Allowable operating temperature | 0°C | -20~+40 | ||

Production workshop show

ISO9001 certificate

| Packaging Detail:Container transport |

| Delivery Detail:15 days after getting the Advance payment |