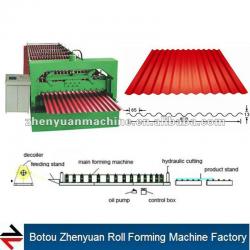

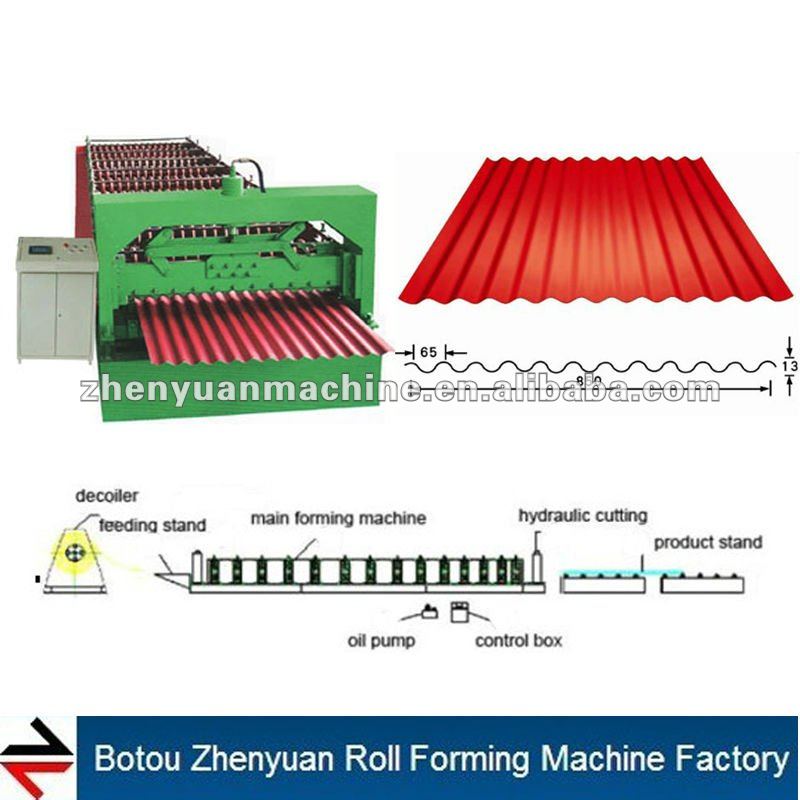

Corrugated roll forming machine/steel profile machine/metal panel corrugated machine

| Type:Tile Forming Machine | Tile Type:Colored Steel | Use:Roof | Place of Origin:Hebei China (Mainland) |

| Brand Name:zhenyuan | Model Number:YX13-65-850 | Attn:Mr.Sam Ou | TEL:0086-13480903152 |

| Certificate:ISO9001 and CE | skype:samuna219 | product function:make roof panels from steel sheet | production:complete line |

| metal thickness:0.3-0.8mm | Address:Fuzhuang development zone,Botou,Hebei,China |

Corrugated roll forming machine/steel profile machine/metal panel corrugated machine

1, about us:

Botou Zhenyuan Roll forming machine factory is a professional manufacturer with good reputation. The factory has specialized in this field since 1998. With high quality, good price and top service, we are supplying the roof roll forming machine and all other steel profile forming machine.

2, Application of roll forming machine:

The panel forming line can manufacture various kinds of beautiful roof and wall panels. Produced panel has a beautiful appearance and bright color, which are widely used in garden, factory, resort, hotel, exhibition hall, vacationland, ancient architectures and modern villa.

1). fast installation and easy to operate

2). Low repair and maintenance costs

3). High-strength, windproof and reliable load-bearing steel structures

4). highly anticorrosion and dustproof

3, Specification and Parameter:

Producing Process Sketch

Decoiling the sheet - guiding - roll forming- measure length - cutting- output to the supporter

Main technical parameters

| Model Type | YX13-65-850 roof panel Machine |

| Sheet material | Pre-painted steel sheet, galvanized or aluminum sheet |

| Thickness of material | 0.3-0.8 mm |

| Width of material | 1000 mm |

| Forming Speed | 8-10m /min |

| Forming steps | 13 steps |

| Main Motor Power | 5.5kw, adopts cycloid cam speed reducer, chain transmission |

| Hydraulic power | 3.0kw |

| Diameter of Roller | Φ75mm. high grade No.45 forged steel, plated hard chrome on the surface of roller with thickness 0.05mm |

| Type of Cutting | Automatic |

| Material of Cutter | Cr12 mould steel with quenched treatment |

| Voltage | match your country |

| Controlling System | PLC Frequency Conversion Controlling System |

1. Hydraulic cutting

2. PLC control cabinet

3, loading of the product:

4, Certificate:

| Packaging Detail:main body of machine loaded into container |

| Delivery Detail:within 25 days after received the deposit |