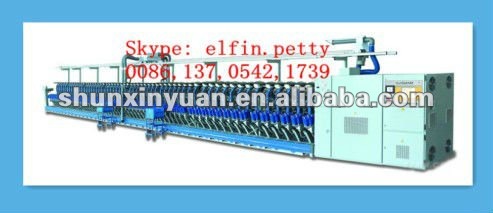

Cone Winding Machines in Textile Machinery/Automatic Sewing Thread Cone Winders/

1)Reduce Your Cost Furthest 2) Automatic Sewing Thread Cone Winders,with excellent reputation in the world market - details see: https://www.machineto.com/cone-winding-machines-in-textile-machinery-automatic-sewing-thread-cone-winders-10277514

| Condition:New | Type:Winder Machine | Place of Origin:Shandong China (Mainland) | Brand Name:Beyond |

| Model Number:JK2008-1 | Spinning Method:Ring Spinning | Automatic:Yes | AUTOMATIC CONE WINDERS:CONE WINDING MACHINES IN TEXTILE MACHINERY |

| SEMI CONE WINDERS:AUTOMATIC CONE WINDERS | HALF CONE WINDING MACHINES:HALF AUTOMATIC CONE WINDERS | | |

Automatic Sewing Thread Cone Winders

| [Specification] |

| Model | JK2008---Automatic winder with manual cop feeding and manual package doffing | | Direction of frame head | right or left hand | | frame | 6 or 8 heads per section | | Number of heads | Max.60 heads | | Materials | Natural fibers,synthetic fibers and blended spun yarns | | Yarn Count range | Nm8.0-Nm80.0 | | Dimensions of tube | L180-350mm *32-55mm | | Winding traverse | 82-155mm | | Delivery speed | 400-2200 m/min with stepless setting | | Splicer | Select the relative splicing gun according to the different yarns | | Grooved drum | Adopt special treated metal | | Drum drive | drive directly bymeans of DC servo motor | | Single spindle actin | control to finish the actions independently by five step-by-step motors | | Computer inteligent winding | control the drive ratio between drum and package by means of computer | | Yarn tension control | intelligent close-loop tension control ensures yarn tension uniform | | Increase of package taper | 0°- 5° | | Electronic yarn clearer | permit to select loeofe photoelectiricity clearer or Uster capacitance clearer with comprehensive and continuous yarn and splicing control | | Brake | the complete package will be lifted off immediately as a yarn break,independently equipped with braking devices for drum and cheese | | Centralized setting | yarn tension,package weight balance and anti-shock device pressure,air splicer pressure,pneumatic pressure,delivery speed,fixed lenght,splicing cycle repetition times etc | | Waste gas emission | exhaust from the pipe connected on the top of the frome head | | Cop conveyer hand | convey toward frame tail by automatic or manual start mode | | Optimal use of energy | single spindle actions controlled to drive independently by means of different stop-by-step motors and designed optimized drawing fan

ensure optimal use of energy of entire machine | | Installed power(60 heads) | 25KW | | Optional | 1.waxing device 2.traveling cleaner |

|

1)Reduce Your Cost Furthest

2)Experienced and Professional in machinery field with excellent reputation in the world market

Established in 1952,our company has been specializing in designing,manufacturering and marketing of a full range of textile machinery for many years.We have five branch companies now.Our main products are that blow room/cotton carding machinery/draw frame/roving frame/rotor spinning machinery/ring spinning machinery/water jet loom/nonwoven machinery etc.

Our group has passed ISO9001,ISO14001,ISO13485.The products must meet the technical standards f 3C and CE. All the products are certified by the Industy Administration Authority.We are enjoying an excellent repution in the world market with perfect products and low price.

Welcome to make an inquiry.

You are warmly welcome to visit our factory.

| Packaging Detail:WOODEN OR NUDE |

| Delivery Detail:WITHIN 30 DAYS AFTER GOT THE PAYMENT |

Related Product for Cone Winding Machines in Textile Machinery/Automatic Sewing Thread Cone Winders/