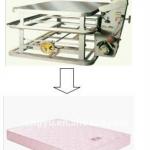

Computer panel saw

| Condition:New | Place of Origin:Shandong China (Mainland) | Brand Name:MNTools | Model Number:MTSK260 |

| Power(W):7.5kw |

Computer panel saw

Technical Parameters

| Model | MTSK260 | MTSK320 | MTSK380 |

| Gross weight | 4200KG | 4500KG | 5000KG |

| Workbench size | 2600MM | 3200MM | 3800MM |

| Machine length | 4630MM × 5500MM | 5230MM × 6400MM | 5830MM × 5500MM |

| Pressure | 6kg/cm2 | 6kg/cm2 | 6kg/cm2 |

| Power supply | 380V | 380V | 380V |

| main motor power | 7.5KW | 7.5KW | 7.5KW |

| feeding driving power | 1.5KW | 1.5KW | 1.5KW |

| feeder power | 1KW | 1.5KW | 2KW |

| saw blade projectin height | ≤80MM | ≤80MM | ≤80MM |

| cutting length | 2440MM | 3050MM | 3660MM |

| cutting speed | 0-50M/MIN | 0-50M/MIN | 0-50M/MIN |

| cutting straightness precision | 0.20MM/2440MM | 0.20MM/2440MM | 0.20MM/2440MM |

| feeding precision | ±0.3MM | ±0.3MM | ±0.3MM |

| catercorner precision | 1200/2400 < 0.7MM | 1200/2400 < 0.7MM | 1200/2400< 0.7MM |

| feeding speed | 25~ 30M /MIN | 25~ 30M /MIN | 25~ 30M /MIN |

| feeding length | 2440MM | 3050MM | 3670MM |

| pneumatic unit | Taiwan Actac | ||

| electric units | Touch screen , servo motor , servo driver , tranducer , PLC and text display are all made in TAIWAN; swiches and AC contactor: from France, stroke switch: Japan. Motor made in China | ||

| feeding and returning convey mode | gear and rack | ||

| speed adjust | transducer | ||

| feeding rack | pneumatic floating beads | ||

| positioning mode | pulse servo position control | ||

| main saw size | Outer diameter φ 350MM inner diameter φ 30MM thickness 4.4MM | ||

| scoring saw size | Outer diameter φ 1800MM inner diameter φ 30MM thickness 4.3 -5.3MM | ||

| assistant saw size | Outer diameter φ 280MM inner diameter φ 30MM thickness 4.4MM | ||

| main saw rotation | 5000rpm | ||

| scoring saw rotation | 7000rpm | ||

The above data is for reference. Any modification is subject to the real products | |||

Characteristics:Auto detectio nof plates, return to origianl operation condition soon after the cutting of plates required. The speed of cutting is cont no lled by inverter, applicable to plates of different thickness and quality. Feeding by preunmatic float ball table, for easy operation of thick plates. Auto feeding by robboot, with low labor streng thand high productione fficiency. Original computer digital control auto position to stop artificiale rrors and greatly improve the precision of dimension. The perfect completion of follow-up dustcollection system, to fully satisfy your demend on highquality.

| Packaging Detail:exporting package |

| Delivery Detail:30days |