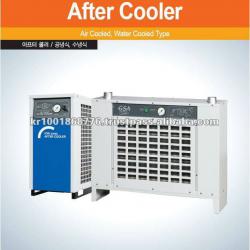

Compressed Air Aftercooler

| Place of Origin:Gyeonggi-do South Korea | Brand Name:GSA | Model Number:HYA | Structure:Plate Heat Exchanger |

| Liquid Flow Rate:300 m3/min | Maximum Working Pressure:15 barg |

GSA HYA series Aftercooler Air-cooled type

Compressed Air Aftercooler

Aftercooler

Industrial Aftercooler

Aftercoolers are heat exchangers for cooling the discharge from

an air compressor.

Aftercoolers control

the amount of water vapor in a compressed air system by condensing the water

vapor into liquid form. An aftercooler is necessary to ensure the proper

functionality of pneumatic or air handling devices that are a part of process

manufacturing systems

Aftercoolers are heat exchangers for cooling the discharge from anair compressor.

Aftercoolers control the amount of water vapor in a compressed air system by condensing the water vapor into liquid form.An aftercooler is necessary to ensure the proper functionality of pneumatic or air handling devices that are a part of process manufacturing systems

Air cooled aftercoolers use ambient air to cool the hot

compressed air. The compressed air enters the air cooled aftercooler. The

compressed air travels through either finned tubes or corrugated aluminum

sheets of the aftercooler while ambient air is forced over the cooler by a

motor-driven fan. The cooler, ambient air removes heat from the compressed air.

Features & Benefits

- Flow range of 35-3355 scfm (1-95 m3/min.)

- As much as 60% of the water in compressed air can be removed

- Advanced technology designs to maximize heat transfer with minimum

pressure drop. - Corrosion resistance construction.

Durable

aluminum plate core design saves space and minimizes energy

Air cooled aftercoolers use ambient air to cool the hot compressed air. The compressed air enters the air cooled aftercooler. The compressed air travels through either finned tubes or corrugated aluminum sheets of the aftercooler while ambient air is forced over the cooler by a motor-driven fan. The cooler, ambient air removes heat from the compressed air.

Features & Benefits

- Flow range of 35-3355 scfm (1-95 m3/min.)

- As much as 60% of the water in compressed air can be removed

- Advanced technology designs to maximize heat transfer with minimum pressure drop.

- Corrosion resistance construction.

Durable aluminum plate core design saves space and minimizes energy

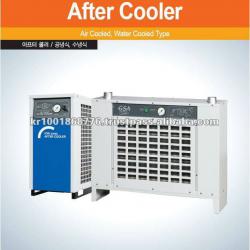

| Packaging Detail:Export standard |

| Delivery Detail:2 weeks |