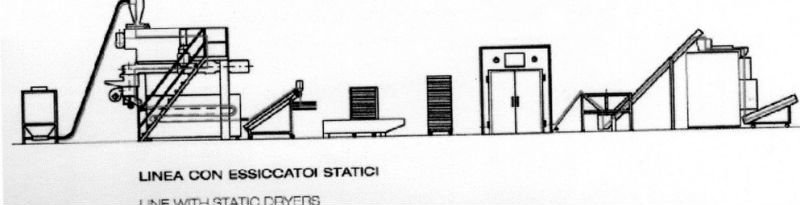

complete line for production of dry pasta, long and short

| Place of Origin:Italy | Brand Name:VITANZA CLAUDIO | Model Number:k300-600 | Production Capacity:300kg-600kg hours |

2) AUTOMATIC PRESS MODEL ¡§K300¡¨

Automatic continuous press K300 for the production of long pasta, consisting of:

„h Volumetric type water do ser in order to obtain a constant dosing of liquids and to achieve a

regular flour humidification

„h Volumetric type flour do ser by scroll feeding. Adjustment through motor driven by inverter.

Flour feeding chamber equipped with sensors for maximum and minimum levels. Stirrer with

geared motor.

„h Turbine pre-mixer with liquid sprinkling so to achieve a perfect humidification of all semolina

particles. The turbine is composed by a shaft with rotary paddles which rotating at the maximum

speed gives the assurance to obtain a good mixture where all particles are humidified in the

correct way avoiding clots formations.

„h Kneading vat with main shifting shaft equipped with adjustable paddles for product feeding.

Sliding gate to help emptying the kneading vat in order to permit a very fast and carefully

cleaning. Kneading vat managed by a geared motor.

„h Mechanical device for vacuum system equipped with rotating valve in cast iron managed by a

fixed turns geared motor.

„h Second vacuum mixer for in feed scroll feeding connected directly to the extruding chamber.

Plexiglas cover to control product loading. Sensor for ¡§product high level¡¨ detection.

„h All mixers are equipped with three phases asynchronous oil bath geared motors lubricated for life.

All mixing shafts paddles in stainless steel

„h Vacuum pump at machine side or at machine interior

„h Compression unit with chromate and hardened scroll mm.140 of very high quality driven by an

electronic geared motor to choose the optimal maximum speed. Thrust bearing unit with roller

and bath oil axials. Reduction gear and motor managed by an electronic device system.

„h ROUND HEAD with diffuser and digital pressure control. Constant control of head pressure and

temperature. Machine stop at maximum pressure. Die extraction by hydraulic system Die with a

300 mm. diameter with seal and automatic discharge.

Cooling centrifuge fan and pasta discharge placed in an ideal position so to permit to the pastaTo drop directly in the pre-drying unit. Visual control of pasta production„h Electronic panel with wheels for positioning at machine side for control of all machineoperations. Main board in accordance with all safety rules„h Stainless steel structure complete with legs, ladder with carbon steel scaffold.

3) AUTOMATIC CLOSED CIRCUIT UNIT for cooling the extrusion pipe and head.

Refrigeration through gas R404. The system allows to work at controlled temperature

In order to produce also short pasta you need:

NO. 1 CONVEYOR FROM PRESS K300 TO TRABATTO FOR SHORT PASTA

NO. 1 PRE-DRYING UNIT FOR SHORT PASTA

Shaker pre-drying unit for short pasta composed by no. 8 shaking vibrating tiers with stainless steel

net (mesh mm2 0,5) adjustable product advancing speed. Output: 300 Kg./h

TECHNICAL FEATURES

Short pasta with be transported on the stainless steel net shaken by a vibrator.

Base and complete structure in stainless steel.

The tiers movement mechanism is generated by brackets system

Insulating panels in polyurethane with inner and outer surfaces in stainless steel.

Asynchronous three phases motors with high temperature power resistance managing centrifuge fans.

Electric finned resistance or overheated water battery

Digital plant for temperature control

NO. 24 TROLLEYS WITH TRAYS FOR SHORT PASTA FOR DRYERS EC100

PACKING MACHINE FOR DRY SHORT PASTA

WEIGHING-FILLING-SEALING MACHINE MOD. BG 37/IM-1 composed by:

NO. 1 HOPPER: in stainless steel AISI 304 and aluminium. The product is discharged on the

vibrating channel in stainless steel – dimpled and teflon coated -and conveyed towards the infeed

conveyor. Product flow is controlled by an adjustable gate and the flowing speed is controlled by a

potentiometer

NO. 1 INFEED CONVEYOR: in stainless steel AISI 304.

NO. 1 ELECTRONIC WEIGHING UNIT: body in stainless steel AISI 304

Vibrating channel in stainless steel AISI 304 – dimpled and Teflon coated- adjustable vibration speed

Vibrating channel is divided into 2 sectors – 1 for rough weight, 1 for accurate weight.

Electronic loading cell fitted with electronic weight control device for setting of the roughing,

accuracy and vibration speed

Scale self-calibration

Mix-max weight: from 50 to 2000 grams (according to product volume)

Weight accuracy is subject to:

Feeding of the product at a constant rate so as to maintain a constant level inside the machine

hopper

Constant bulk density

Cleaning of the filling areas at regular time interval

NO. 1 VERTICAL PACKING MACHINE - body in aluminium and stainless steel AISI 304

Machine functions performed by PLC + TOUCH SCREEN display to set up all packing machine

functions

Possibility of recalling stored programs

No. 1 forming tube in stainless steel AISI 304 suitable for packing of bags with following size:

Width: min mm. 100 – max. mm. 245

Length: min mm. 100 – max no limits

Sealing bars: 1 vertical – 2 horizontal

Horizontal sealing bar fitted with hot printer

Thermoheated sealing bars with built-in thermocouples and metallic cover for feeder protection

Pneumatic vertical and horizontal sealing bars

Easy shift of the vertical sealing bar to make easier maintenance on the forming tube

Draw-belts covers in stainless steel AISI 304

Film drawing by draw-belts with independent control of the operating pressure through regulators

Position ON-OFF for the automatic approach of the draw-belts to the forming tube

Length adjusting and sizing by means of PLC

Bags counter with electronic stop on reached programmed number of bags

Alarm for film end, reached number of pre-set number of bags, end of dater tape

Power: 220V single phase 50 or 60hz

Films: coupled, PP or laminated

Film width: max. mm. 540

Bags weight: from 20 to 2000 grams (according to product volume)

Output capacity: about 10 bags / minute (500 gr) but anyhow subject to:

Uninterrupted product flow

Uniformity of film thickness

Connection of the machine to an effective air pressure system

Strict maintenance of the machine as per our instruction manual

NO. 1 DISCHARGE CONVEYOR – in stainless steel AISI 304

Parts touching the product are suitable for food product

Conveyor fitted with motor and gear motor

Size of the conveyor: about cm. 192 (length) x cm. 31 (width)

NO. 1 PHOTOCELL FOR PRINT CENTERING

“ PRICE” PROPOSALS

NO. 1 FLOUR ELEVATOR x 700 kg

NO. 1 PRESS K300 WITH NO DIE

NO. 7 EACH BRONZE DIE

NO. 2 SPECIAL DIES PRE-FILTER

NO. 3 KNIVES SET SIZE PASTA

NO. 1 DIE FOR “PENNE” WITH SPECIAL CUTTER

NO. 1 COOLING UNIT

NO. 6 DRYING CABINETS EC100

NO. 1 CONVEYOR FROM PRESS K300 TO TRABATTO

NO. 1 PRE-DRYER FOR SHORT PASTA

NO. 24 TROLLEYS WITH TRAYS FOR DRYER

NO. 1 PACKAGING MACHINE “BG 37 IM-1

(as described with no accessories)

NO. 10 DAIS X ASSEMBLY X 2 technical

TOTAL PRICE LINE EURO € 350.000,00

TOTAL PRICE U.S. Dollars AMERICAN 462.000,00

| Packaging Detail:request installation and staff training at your company |

| Delivery Detail:180 day |