competitive price toughened glass machinery with CE approved

| Condition:New | Machine Type:Glass Cutting Machine | Production Capacity:75 sets every week | Place of Origin:Hubei China (Mainland) |

| Brand Name:JOY | Model Number:1525 | Voltage:220V \380V,220V\380V | Power(W):10kw |

| Dimension(L*W*H):1900*2500*300mm | Weight:1000kg | Certification:CE | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas | CE:Available | OEM:Available | Automatic Grade:Automatic |

| Max grooving depth:6-30mm | Max diameter of the knife:170mm | Engraving speed:3m/min | Thickness of glass:3-30mm |

| Gross power:10kw | Main axle rotating speed:4000rpm |

toughened glass machinery

If you have any questions,pls feel free to contact me, i will give you the professional suggestions with 5 hours

contact with cherry

Detailed information for toughened glass machinery :

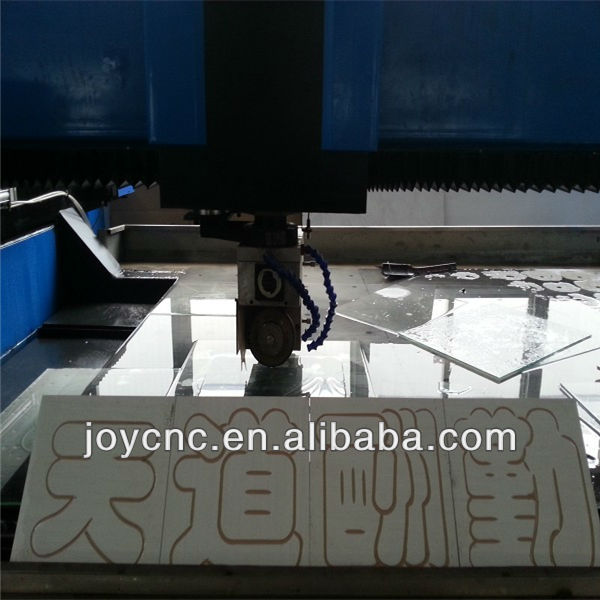

1. CNC glass engraving machine, the new generation of glass processing equipment our company has developed lately.

2. It adopts the computer aided design system, jointly designed by a number of senior engineers and technicians.

3.The machine is equipped with high - quality ball screw, slideway in Germany, and japan's Mitsubishi servo motor.

4. It is controlled by the computer and is able to assign the tools library as well as the tool changing system according to the reqirements.

5.The machine is widely applied in glass and mirror grooving, polishing from the designing to processing.

Advantages for machines for toughened glass machinery :

1. Unique graphic simulation capabilities enables the user to see the sample to be processed easily, significantly decreasing the error rate during processing.

2. Long wheel utilization, tool grinding wheels can working on170 -110, nearly two times of that of the same kind in china, which greatly reduces the production cost for the customer.

3. Both English&Chinese user interface language are available, convinient, easy to operate.

Technical parameters for toughened glass machinery :

| Model | JOY 1925 |

| X,Y,Z working area | 1900×2500×300mm |

| Allocating Accuracy (C axis) | 0-360 |

| Location precision | (X, Y, Z axis) 0.10×0.10×0.02mm |

| Repeatability | (X, Y, Z axis) 0.05×0.05×0.01mm |

| Z aixs | 10m/min |

| Main axle rotating speed | c |

| Main axle rotating rate | 4kw |

| Max grooving depth | 6-30mm |

| Engraving speed | 3m/min |

| Voltage | 220V/380V |

| Thickness of glass | 3-30mm |

| Max diameter of the knife | Φ170mm |

| Gross power | 10kw |

working part for toughened glass machinery :

sample

One-year after-sales service includes:

1. We will offer some of the parts for free in the first year. The buyer needs to pay for the shipping cost for the parts. The user needs to send us pictures of the broken one, then we will send out the part they need.

2. In the first year, if the buyer needs our engineers to come to the local to fix some problems of the machine that they cannot fix by themselves; we will send our engineers for free. The buyer needs to pay the flights, housing and meals for the engineers in the local.

3. We will offer our service through email and phones if the buyer needs any help on technical problems

| Packaging Detail:In wood case ,it product goods well |

| Delivery Detail:7 days after order confirmation |