Coconut shell charcoal briquette machine 0086-15038021962

| Condition:New | Place of Origin:Henan China (Mainland) | Brand Name:Lantian coconut shell charcoal briquette machine | Model Number:LTQ360 |

| Voltage:380v | Power(W):7.5kw | Weight:1850kg | Dimension(L*W*H):1.38*1.62*1.71m |

| Certification:CE9001:2008 and ISO | Warranty:12 months | After-sales Service Provided:Engineers available to service machinery overseas | Color:blue,green,etc. |

| Capacity:4-6t/h | Working hours:20000hours | Moulds:customed | Shape:pillow,egg,ball |

| Raw materials:coal powder,charcoal powder,coconut shell powder | Application:BBQ,firepalce,hot water boilers,industrial use | Size of materials:less than 3mm | Supporting equipments:crusher,mixer,automatic cutter,dryer,conveyors |

| Type:coconut shell charcoal machine |

Coconut shell charcoal briquette machine 0086-15038021962

Coconut shell charcoal briquette machine description

1) Lantian brand coconut shell charcoal briquette machine is mainly used for pressing powder material.

2) Such as, coal powder, charcoal powder, metallic powder (Fe / Si powder), iron scale, iron sludge, precipitator dust, iron concentrate, the final production can be press into ball, oval pillow and egg shapes, etc.

3) Ball press machine mainly used in the pulverized coal forming; Dry powder molding; The desulfurization gypsum molding; Coke powder molding; Iron ore and all kinds of metal powder molding, etc.

Working principle of coconut shell charcoal briquette machine

[1] First, the powder material will be transferred on to the two pressure roller through thefeeder.

[2] The natural materials enter the ball roll mode with the roll rotation.

[3] Material pressure on a small part become larger, when the material enter into the two pressure rollers, the pressure of materials has reached the peak.

[4] Tremendous pressure between the two roller, the powder become finished product.

The requirements of raw materials

1.The materials powder size must be less than 4 cm. If not, you should crush it firstly.

2.Any raw materials with metal is not allowed, otherwise it will damage the surface of rollers.

Mainly technical parameters of coconut shell charcoal briquette machine

| model | motor power(kw) | capacity (t/h) | speed radio | diameter(mm) | weight(t) |

| 290 | 5.5 | 2-4 | 1:12.26 | 290 | 0.75 |

| 360 | 7.5 | 3-6 | 1:23.34 | 360 | 1.67 |

| 400 | 13 | 4-10 | 1:23.34 | 400 | 2.7 |

| 500 | 22 | 5-12 | 1:31.5 | 500 | 4.1 |

| 650 | 30 | 10-20 | 1:31.5 | 650 | 5.7 |

| 750 | 55 | 15-30 | 1:31.5 | 750 | 8.9 |

| 800 | 75 | 25-30 | 1:31.5 | 800 | 11 |

Carbonization process of coconut shells

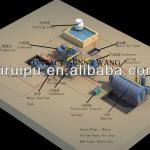

The whole production line

Appplication of final products

1. Home heating stoves; coal ball press machine for BBQ

2. Hot water boilers and the industrial boilers;

3. Easy transportation for powdered materials.

Our guarantee

We have an excellent team work, for this we can guarantee charcoal briquette machine quality and punctual delivery. When the charcoal briquette machine in working time, we can guarantee the capacity you need. for the wearing parts, we can provide the parts with lower price for whole using life.

Our main coconut shell charcoal briquette machine

How to choose a suitable charcoal making machine:

1. What’s the raw material?

As different materials match different machines, So please tell us what’s the raw material, is it limestone powder, coal powder or other metal powder.

2. The moisture of raw material

The moisture determines whether dryer is needed in the process.

3. The size of raw material

It should be crushed if the size is too big.

4. Capacity you need

Different capacity match different models of machine, what’s more, the smaller the capacity is, the simpler the process will be.

Service

1. Before Sale: help you to set a purchase plan according to your requiremen.

2. During Sale: accompany you to check the performance of the machine; train technical stuff for you

3. After Sale: Sent artisan to your place and help you with the installation

| Packaging Detail:1.Export standard container 20GP, it include simple production line,such as shisha briquette machine,wheel mixer,binder making hopper,samll crusher 2.40 GP include the whole production line, from curshing to molding to drying, 3. If your production line is very big, you can choose 40HQ, FR container.4. one set machine in bulk 5.The spare parts in wooden case 6.Or as your requirement |

| Delivery Detail:10 days for one set machine,20 working days for whole line |