Coal Mill/Coal Grinding Mill/Coal Ball Mill

| Condition:New | Type:Ball Mill | Motor Type:ANY | Power(W):155kw |

| Capacity(t/h):6.5-36t/h | Place of Origin:Shanghai China (Mainland) | Brand Name:Minggong | Model Number:2100*3000 |

| Dimension(L*W*H):2100*3000 | Certification:CE ISO9001:2000 | Warranty:1 YEAR | After-sales Service Provided:Overseas service center available |

| model:2100*3000 | grinding media weight:15t | power:155kw | rotated speed:23.7r/min |

| working life:normal life span | discharge scope:0.074-0.4mm | key word:coal mill / grinder machine / grinder mill | key words:coal mill/coal grinding mill/coal ball mill |

| keyword:coal mill/coal grinding mill/coal ball mill | keyworkds:coal mill/coal grinding mill/coal ball mill |

Coal Mill

coal mill/coal grinding mill/coal ball mill

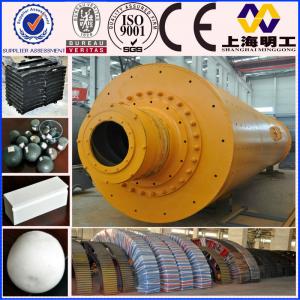

Coal millis major equipment of cement plant and used for drying and grinding coal. The equipment is mainly consisted of feed device, main bearings, rotating parts, drive device, selling device, high-voltage start-up device and lubrication system. The raw material is fed into mill by feeding equipment. The hot wind enters into the mill by inlet end. As the mill cylinder rotates, the coal and hot air exchange heat in the mill. The coal is crushed and grinded in the mill. When the coal is being grinded, the powder is brought out of the mill by the hot air going through the mill. The products have got the international quality certification of ISO9001:2000 and the European CE certification.

Thecoal millwe make is with reasonable structure, high grinding efficiency and is the ideal equipment for coal processing.

| Ball Mill | Materail |

| 1 Feeding Device | ZG270-500 |

| 2 Bearing For Main Shaft | 40Cr |

| 3 Feeding Cover | ZGMn13 |

| 4 Fan-Shaped Liner | ZGMn13 |

| 5 Cylinder | Q235A |

| 6 Liner | ZGMn13 |

| 7 Gear Rim | 40Cr |

| 8 Discharging Cover | ZG270-500 |

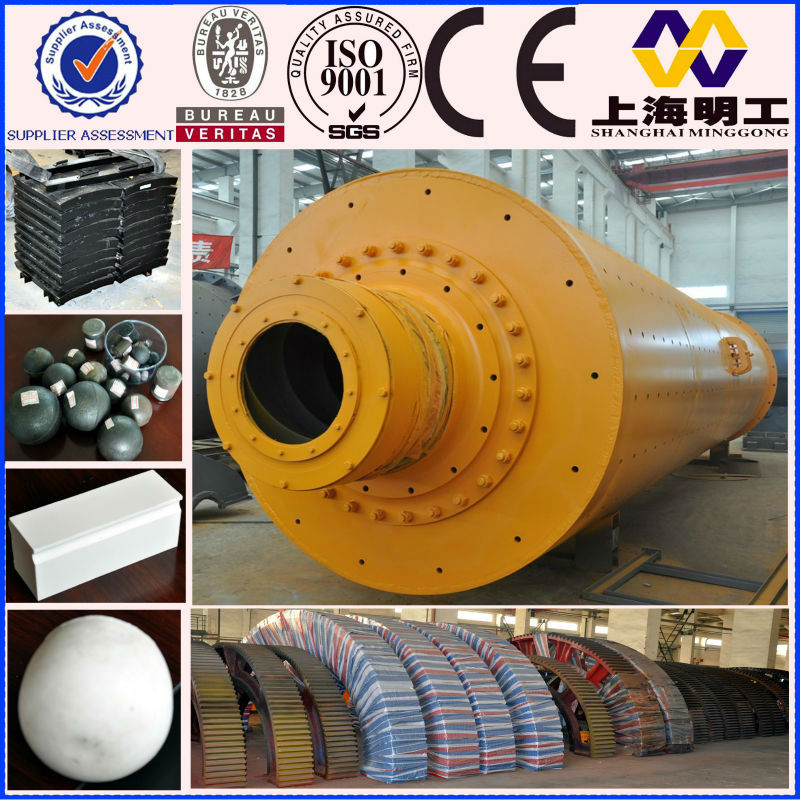

| Item | Model(m) | Production Capacity(T/H) | Grinder Style | Rotate Style | Power(KW) | Reducer | Weight(T) | |

| Model | Speed Ratio | |||||||

| 1 | Φ1.7×2.5m | 3-5 | Circle | Edge | 95 | ZD40 | 4.5 | 22 |

| 2 | Φ2.2×3m | 5-6 | Circle | Edge | 180 | ZD 50 | 4.8 | 31.48 |

| 3 | Φ2.4×4.4m | 8-9 | Circle | Edge | 240 | ZD 60 | 6.4 | 36.2 |

| 4 | Φ2.4×4.75m | 12 | Circle | Edge | 280 | ZD 60 | 4.5 | 47.53 |

| 5 | Φ2.5×3.9m | 10 | Circle | Edge | 320 | ZD 60 | 4.5 | 56.8 |

| 6 | Φ2.9×4.1m | 20 | Circle | Edge | 480 | JD×560 | 4.9 | 73.79 |

| 7 | Φ2.8×5.75+2.25m | 16-17 | Circle | Edge | 500 | JD×630 | 4.5 | 106 |

| 8 | Φ3×6.5+3.5m | 20 | Circle | Edge | 630 | JD×800 | 5 | 118.3 |

| 9 | Φ3.5×6m | 50 | Circle | Edge | 1000 | JD×630 | 6.7 | 139 |

| 10 | Φ3.8×7.2m | 85 | Circle | Edge | 1400 | JD×710 | 4.58 | 227 |

| 11 | Φ3.8×7.5m | 90 | Circle | Edge | 1600 | JD×900 | 5.6 | 233 |

Contact Add:No.33 Shenxia Road, Malu Industrial Park, Jiading District, Shanghai, China

coal mill/coal grinding mill/coal ball mill

coal mill/coal grinding mill/coal ball mill

Coal Mill

coal mill is the key equipment for re-crushing, it is widely used for dry or wet powder grinding operation of ore grinding before dressing ferro

us and non-ferrous metal, raw material or finished product of cement, chemical industry, novel construction material, refractory material, etc. The machine is composed by feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control).The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance. The machine is with stable and reliable working condition.

Moreover, according to different materials and discharging methods, there are dry coal mills and wet ball mills for choice. our company owns the leading technology and rich practical experience, and we can offer 360ºservice, and leave you from any worry.

coal mill/coal grinding mill/coal ball mill

------About us

| Shanghai Minggong Heavy Equipment CO., LTD is one high-tech enterprise, which involves R&D, production, sales and service as well. In the past 20 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the solution of making high grade sand and matched equipments. |

| The head office of Shanghai Minggong is in Shanghai- the international financial centre. Here we have modern production base of Eighteen thousands square meters, professional R&D institution and technology team, which make us world-class company. Here all Minggong machines are designed produced, assembled and texted according to the ISO9001:2008. Till now, our products are sold to 130 countries, being the popular equipments in global crushing and grinding industry. With the development of our Shanghai Minggong , we would like to help more and more customers start their business in mining and construction industries, offer them the best solution, much more advanced machinery and better service. |

SUPPORT

| We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience. |

Ball Coal Mill/Ball Mill For Ore/Raymond Ball Mill

| Packaging Detail:coal mill/coal grinding mill/coal ball mill with standarded exported packaging, bulk cargo |

| Delivery Detail:20days after receiving the deposit(Ball Mill) |