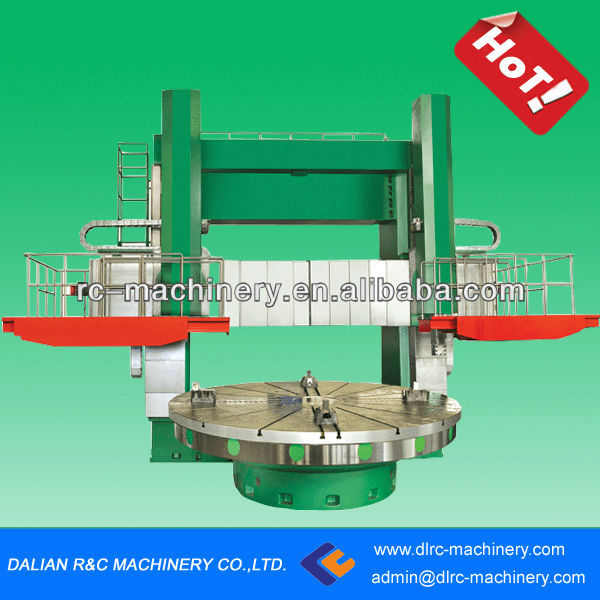

CK5240 Double-column Turret Vertical Lathe machine

| Condition:New | Type:Vertical | CNC or Not:CNC | Automatic Grade:Automatic |

| Max. Swing Diameter:4000mm | Place of Origin:Liaoning China (Mainland) | Brand Name:R&C | Model Number:CK5240 |

| Voltage:380V,60HZ | Power(W):DC55(kw) | Dimension(L*W*H):6680*5700*4870 | Weight:40/50/60 t |

| Certification:ISO9001 & CE | After-sales Service Provided:Engineers available to service machinery overseas | color:as you need | control system:Electrical apparatus |

CK5240 Double-column Vertical Lathe

Ⅰ. Our Company

1.Company Introduction:

We are one of the leading machinery group specializing in producing heavy duty machine tools, it have five factories in China which mainly produce Vertical Lathe, Boring & Milling Machine, Heavy-duty Horizontal Lathe, both conventional and CNC types.

We have a group of professional engineers in charge of technology, manufacturing, installing and testing, so we can guarantee that our machines will put on good performance based on high quality.

2.Export Market:

Our products have been exported to more than 60 countries such as Canada, the U.S.A., Italy, France, Brazil, Bolivia, Chile, Russia, Romania, Saudi Arabia, Syria, Jordan, the U.A.E., Indonesia, Singapore, Thailand, India, Pakistan, South Africa, Egypt, Nigeria, Kenya and so on.

3.Our Belief:

We do believe we can create a win-win situation for both sides as long as we have come to a cooperation consensus. "Together we stand still, Divided we fall" this is what we treat our partners. Clients from all over the world are warmly welcome to build business relations, cooperate and develop together with us. Please feel free to contact us for details.

Ⅱ.Our Products

4.Description:

Being universal and heavy-type CNC double-column vertical lathe, the vertical lathe is suitable for high-speed steel and hard alloy cutter, rough and fine turning processing of inner and outer cylindrical surface, conical surface, plane, all kinds of rotary surface and grooving offerrous metals,nonferrous metals and some non-metallic parts.

5.Features:

The CNC double-column model CK5240 is a super rigid vertical lathe machine with big machining capacities, stable and rigid structure, heavy job load and high machining efficiency.

The vertical lathe machine is equipped with two vertical tool heads. Rigid vertical tool heads are equipped with big rams for optimum power cutting performance.

AC variable frequency motor is used to achieve speed change.

Gears are made of 40 Cr steel and precision ground for high precision and low vertical lathe machine noise.

6.Machine Main Structure:

1. Structure type: The vertical lathe is of gantry type structure. The left and right stand column, articulated beam and other large parts are made from high strength, low stress HT250 cast iron. The hardness is HB170-190.

2. Workbench: The workbench adopts hydrostatic guideway.

3. Bearing: Radial axis of the bearing adopts high-precision NN30(D step) bearing. It had high precision, strong bearing capacity.

4. Beam: To ensure the accuracy of the machine, the beam is made from high strength, low stress HT300 cast iron. To extend the life of the machine, the contact surface of beam and stand column guideway is made of wearable Zn-Al alloyplates.

5. Rail head: The axis making level and vertical movement is drove by independent AC servo motor. The AC servo motor of vertical movement adopts ball screw transmission, improving the transmission efficiency of any axis.

6. Speed changing box: The material of gears is of high-frequency quenching handling of high quality alloy steel. The hardness can reach HRC45-50, the accuracy can reach 7 series. The speed changing box is of vertical type and not easy to beat teeth.

7. Hydraulic system: The hydraulic station has blocking, flow and pressure protection, the machine will stop working automatically if it is beyond the reach of operating requirements.

8. Numerical control system: Standard Siemens 802D system, matched DC main axis drive and AC feeding drive.

7.Machine specifications:

| Name | Unit | CK5240 |

| Max cutting diameter of workpiece | mm | 4000 |

| Workbench diameter | mm | 3200 |

| Max height of workpiece | mm | 2500/3150 |

| Max weight of workpiece | t | 32 |

| Workbench speed range | r/min | 0.5~45 |

| Workbench speed series | step | two gears no step |

| Max cutting force of right knife rest | kn | 40 |

| Max cutting force of left knife rest | kn | 35 |

| Max workbench torque | kn.m | 63 |

| Cutter feeding scope | mm/min | 0.12~145 |

| Rapid movement speed of knife rest | mm/min | 2400 |

| Beam movement speed | mm/min | 350 |

| Turning angle of vertical slide | ° | ±30 |

| Knife carrier size | mm | 40*50 |

| Main motor power | kw | DC55 |

| Machine dimensions(L*W*H) | mm | 6680*5700*4870 |

| Machine weight | t | 40/50/60 |

Note: Manufacturer reserves the right to improve & modify without prior notice.

8.Our Vertical Lathe Products Photo:

9.Parts of the Vertical Lathe:

10.Our Factory:

11.Our Workshop For Vertical Lathe:

12. With customers:

13.After-sale service:

The full machine warranty is 1 year. The seller will offer maintenance free service in the warranty period (except the damage caused by the user’s own reasons).

14.Main export markets:

Albania, Saudi Arabia, Indonesia, Iran, Brazil, Ukraine, Paraguay, Egypt

| Packaging Detail:wooden case suit for sea transportation |

| Delivery Detail:1-3month |