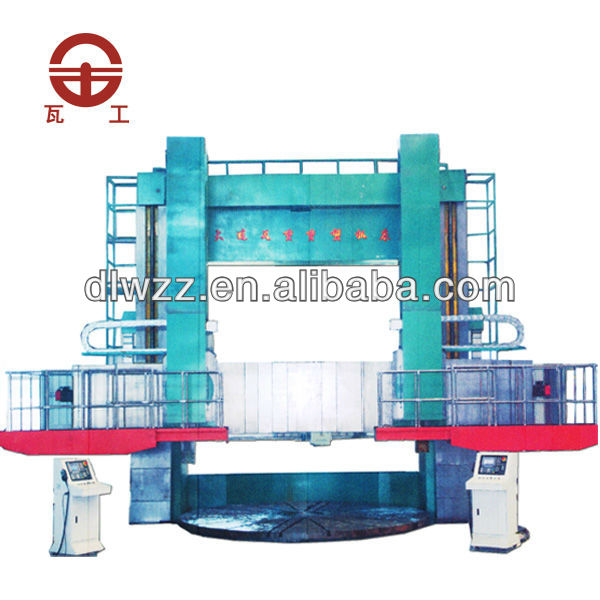

CK5240 CNC HEAVY DUTY TURRET VERTICAL LATHE MACINE

| Condition:New | Type:Vertical | CNC or Not:Normal | Automatic Grade:Automatic |

| Max. Swing Diameter:4000mm | Place of Origin:Liaoning China (Mainland) | Brand Name:DLWG | Model Number:CK5240 |

| Voltage:380V | Dimension(L*W*H):5410X7150X6750mm | Weight:41t | Certification:ISO9001:2008 |

| After-sales Service Provided:Engineers available to service machinery overseas | Material::HT250 casting iron | Usage::Turning,grooving | Bearings::Famous brand like Wafangdian bearings |

| Features::Scraping by hand | Certificate:ISO9001:2008 | Device:Digital readout DRO (cnc is available) | Precision:High precision |

| Guarantee:One year guarantee | Installation:Offer technical support |

1.Advantages:

a. The machine is applied to adopt high speed steel and carbide-tipped cutter to conduct rough and fine turning processing of internal or external cylindrical face, internal or external conical face, nicking etc. procedures made of various ferrous metal, non-ferrous metal and some nonmetal materials.

b. Working table adopts hydrostatic guide way.

c. The spindle is to use model QT600-3 bearing and able to turn precisely.

d. Gear case is to use 20Cr Mn Ti gear wheel of gear grinding, which has high precision and little noise.

e.Centralized lubricating oil supplying is convenient

f. Castings of lathe are to use lost foam foundry (short for LFF)technique. Castings are wearable with good quality and dealt by aging.

2. Main specification and parameters

| Name | Unit | CK5240 |

| Max.turning diameter | mm | 4000 |

| Table diameter | mm | 2830 |

| Max.height of workpiece | mm | 2000 |

| Max.weight of workpiece | T | 10 |

| Range of table rotate speed | r/min | 2~63 |

| Max.torque of table | KN·m | 55 |

| Max.cutting force of right tool post | KN | 26 |

| Horizontal travel of right tool post | mm | |

| Vertical travel of right tool post | mm | 2150 |

| Feeding range of right tool post | mm/min | 0.25~90mm/min |

| Max.cutting force of left tool post | N | 40 |

| Horizontal travel of left tool post | mm | 2160 |

| Vertical travel of left tool post | mm | 1250 |

| Swing angle limit of vertical tool post | degree | ±30° |

| Section size of tool bar | mm | |

| Beam travel | mm | 2350 |

| Beam lifting speed | mm/min | 350 |

| Fast moving speed of tool post | mm/min | 2000 |

| Overall size of machine(L*W*H) | mm | 5410X7150X6750 |

| Power of main motor(DC) | KW | 55 |

| Machine weight | T | 41 |

3.Product features

All the junction surfaces of the complete set are complete by manual scraping and processing techniques.Table is floated by static pressure;the main shaft adopts dual-column cylindrical roller bearings.The mechanical action of the complete set is controlled by PLC digital centralized control to realize mechanical &electrical intergration.Digital wave-band switch controls electromagnetic speed-variation,thus realizing the electro-hydraulic conversion.The complete set complies with all the accuracy requirements.It is fault free,easy in operation and swift in speed variation.It is high efficiency and low noise when processing workpieces.

4.Process and configuration of parts

a.The castings have undergone the annealing treatment at a temperature of 550°Cto remove internal stress.

b.The static pressure guide rail plate is made of aluminum-copper-zinc alloy,which may reduce the temperature of floating oil film promptly.

c.The rigidity of the complete set is reinforced after the sliding surface is treated with manual scraping and manual micro-gap matching.

d.The mainshaft bearing applies the word famous brand--”ZWZ”heavy loading 3182 series dual-column cylindrical roller bearing.

e.The electrical devices are inclusive of the contactor and breaker made by Schneider,France,and PLC made by Mitsubishi,Japan,which are dependable in performance.

5.After-sale Service:

a.The full machine warranty is 1 year.

b.If there is something wrong with the lathe, the after-sale service personnel will reach the buyer within the specified time to determine fault, and remove it.

6.Main Export Markets:

· Great efficient, high accurate, trouble free, and carefree effects with small investment, our machine sell well in both domestic and overseas markets, we have been exported to to Chile, India, USA, Russia and more than 20 countries.

Certificate

Machine parts

Worktable base

Scraped by hand

| Packaging Detail:wood packaging. |

| Delivery Detail:20days for Dalian Port |