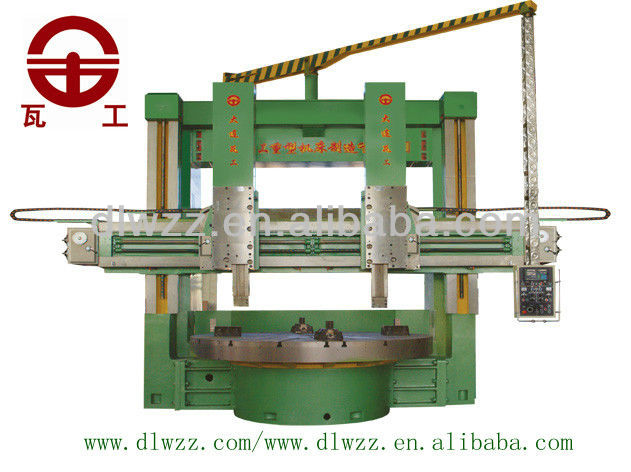

CK5225 CNC DOUBLE-COLUMN VERTICAL LATHE

| Condition:New | Type:Vertical | CNC or Not:CNC | Automatic Grade:Automatic |

| Max. Swing Diameter:2500mm | Place of Origin:China (Mainland) | Brand Name:DLWG | Model Number:CK5225 |

| Voltage:380V | Power(W):DC55 | Dimension(L*W*H):5180*5200*4870 | Weight:33T |

| Certification:CE/ISO9001/2008 | After-sales Service Provided:Overseas service center available | Features:Scraping by hand | Usage:Turning,grooving |

| Material:High Grade Cast Iron | Colour:According to customer's requirements excpt standar one |

CK5225 CNC DOUBLE-COLUMN VERTICAL LATHE

1. Descriptions:

Being universal and heavy-type CNC double-column vertical lathe, the lathe is suitable for high-speed steel and hard alloy cutter, rough and fine turning processing of inner and outer cylindrical surface, conical surface, plane, all kinds of rotary surface and grooving offerrous metals,nonferrous metalsand somenon-metallicparts.

2. Features:

The CNC double-column model CK5225 is a super rigid machine with big machining capacities, stable and rigid structure, heavy job load and high machining efficiency.

The machine is equipped with two vertical tool heads. Rigid vertical tool heads are equipped with big rams for optimum power cutting performance.

AC variable frequency motor is used to achieve speed change.

Gears are made of 40 Cr steel and precision ground for high precision and low machine noise.

3. Specifications:

| Name | Unit | CK5225 |

| Max cutting diameter of workpiece | mm | 2500 |

| Workbench diameter | mm | 2250 |

| Max height of workpiece | mm | 1600/2000 |

| Max weight of workpiece | t | 15 |

| Workbench speed range | r/min | 2~63 |

| Workbench speed series | step | two gears no step |

| Max cutting force of right knife rest | kn | 35 |

| Max cutting force of left knife rest | kn | 30 |

| Max workbench torque | kn.m | 63 |

| Cutter feeding scope | mm/min | 0.12~145 |

| Rapid movement speed of knife rest | mm/min | 2400 |

| Beam movement speed | mm/min | 350 |

| Turning angle of vertical slide | ° | ±30 |

| Knife carrier size | mm | 40*50 |

| Main motor power | kw | DC55 |

| Machine dimensions(L*W*H) | mm | 5180*5200*4870 |

| Machine weight | t | 33 |

4. Machine Main Structure:

1. Structure type: The lathe is of gantry type structure. The left and right stand column, articulated beam and other large parts are made from high strength, low stress HT250 cast iron. The hardness is HB170-190.

2. Wor kbench:The workbench adopts hydrostatic guideway.

3. Bearing: Radial axis of the bearing adopts high-precision NN30(D step) bearing. It had high precision, strong bearing capacity.

4. Beam: To ensure the accuracy of the machine, the beam is made from high strength, low stress HT300 cast iron. To extend the life of the machine, the contact surface of beam and stand column guideway is made of wearable Zn-Al alloy plates.

5. Rail head: The axis making level and vertical movement is drove by independent AC servo motor. The AC servo motor of vertical movement adopts ball screw transmission, improving the transmission efficiency of any axis.

6. Speed changing box: The material of gears is of high-frequency quenching handling of high quality alloy steel. The hardness can reach HRC45-50, the accuracy can reach 7 series. The speed changing box is of vertical type and not easy to beat teeth.

7. Hydraulic system: The hydraulic station has blocking, flow and pressure protection, the machine will stop working automatically if it is beyond the reach of operating requirements.

8. Numerical control system: Standard Siemens 802D system, matched DC main axis drive and AC feeding drive.

5. Our Advantage:

1.All the junction surfaces of the complete set are conmpleted by scraping and processing techniques.

2.Work-table adopt hydrostatic float;

3.The main shaft dual-column cylindrical roller bearing.

4.The mechanical action of rhe compele set is controlled by PLC difital centralized control to realize mechanical& electrical integration.

5.Digital wave-hand switch controls electromagnetic speed-variation. thus realizing the electro-hydraulic conversation.

6.The complete set complies with all the accuracy requirements.It is fault free,easy in operation and swift in speed variation.It is hogh efficiency and low noise when processing workpieces.

7. Our Workshop:

8. Our Certificate:

9. After-sale Service:

- 1.The full machine warranty is 1 year.

- 2.If there is something wrong with the lathe, the after-sale service personnel will reach the buyer within the specified time to determine fault, and remove it.

- Great efficient, high accurate, trouble free, and carefree effects with small investment, our machine sell well in both domestic and overseas markets, we have been exported to to Chile, India, USA, Russia and more than 20 countries.

| Packaging Detail:Seaworthy packing is necessary to protect the goods from the strains of long sea voyage. |

| Delivery Detail:2~4 months |