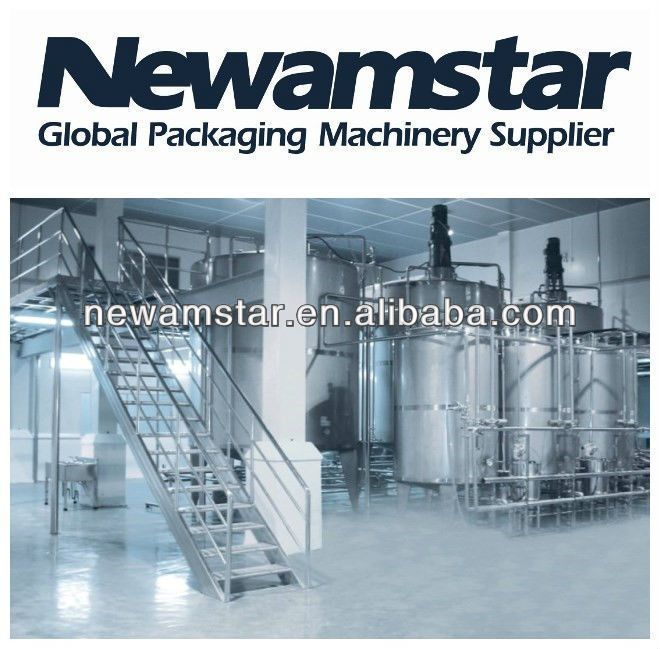

CIP System

| Processing:Washer | Condition:New | Place of Origin:Jiangsu China (Mainland) | Brand Name:Newamstar |

| Model Number:CIP | Processing Types:Juice | Certification:CE | After-sales Service Provided:Engineers available to service machinery overseas |

| Certificate:CE, UL, SGS, ISO, FDA | Material:ANSI304 | Application:Juice,CSD drinks |

CIP(Clean-In-Place)

CIP plays role of rinsing syrup melting system, extracting and dispensing

system for juice, homogenizer, and air exhauster.

UHT sterilization system is attached with the CIP.

It is fully automatically- controlled, automatic confirming of rinsing passage, it

is controlled by the man-machine interface control system, using PLC to fulfill

switch of pneumatic butterfly valves in order to accomplish independent

rinsing. So it can meet the client's requirement of production, synchronous

with CIP units.

The entire rinsing technical index (rinsing time, density of acid and lye, rinsing

temperature, rinsing sequence) can be preset as some program number of

rinsing on the touch screen. When rinsing, it needs manual operation on the

touch screen to designate rinsing equipment, select program number of

rinsing and start the system, then CIP will perform the rinsing process of

designated equipment automatically and in turns according to the pre-set

program.

The system has the function of automatic water-supplement and acid /

lye-supplement, automatic temperature adjustment, displaying the

temperature, density, liquid level, condition of simulating flow and photocell

alarming. Manual and automatic operation is optional to clients; all the indexes

can be revised on the touch screen. Password protection is set to manual

operation and index revision.

| Packaging Detail:Standard Export Packing for Clean-In-Place (CIP) |

| Delivery Detail:50 working days for CIP System |