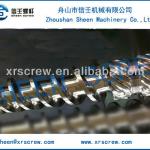

Cincinati 80/173 Twin conical screw barrel for Extruder Machinery

| Place of Origin:Zhejiang China (Mainland) | Brand Name:JIAWEI | Model Number:conical screw barrel | specification:15-300 |

| Material:38CrMoAIA | Hardness of nitration:HV800-1050 | Depth of nitration case:0.4-0.7mm | roughness of the surface:Ra 0.4 |

| Screw straightness:0.015mm | Chrome plating thickness:0.05-0.1mm | Hardness-chrome after nitrition:More than 950HV |

Cincinati 80/173 Twin conical screw barrel for Extruder

Size:screw diameter ø15-ø300mm

Maximum screw length :10000mm

The conical twin screws and barrel can be designed different structure according to the different product and market requests.

Specifications of conical twin-screw and barrel:

| 1.Injection molding machine | Clamping force:250kn-3,2000kn |

2.Single screw extruder | Screw diameter:15mm-360mm |

| LD ratio:15-46 | |

| 3.Conical twin screw extruder | Screw diameter:25mm-92mm |

4.Counter rotating parallel twin screw | Screw diameter:50mm-200mm |

| L/D ration:16-35 | |

| 5.Co-rotating twin screw extruder | Screw diameter:25mm-120mm |

| 45/90 | 45/97 | 50/103 |

| 55/110 | 60/120 | 65/125 |

| 68/146 | 80156 | 80/172 |

| 92/188 |

Double-alloy technical standard:

Double-alloy level:

1.Level A - containing tungsten of 40%

2.Level B - containing tungsten of 25%

3.Level C - containing tungsten of 9.5%

4.Hardness of alloy: HRC56-65o

Applied scope of plastic: applied for PVC and WPC material, has a high output and stable performance.

1.Components of alloy powder: Ni + Co + Cr + W + Si + Fe + B + C

2.Depth of alloy layer: 1.2 mm-2.0 mm

3.Hardness of alloy: HRC>65°

We can manufacture various kinds of screw barrels

1.Hardness of adjuster:HB260-290

2.Hardness of nitration:HV800-1050

3.Depth of nitration case :0.4-0.7mm

4.Fragility of nitration:less than grade 1

5.Rougness of the surface:Ra0.4

6.Linearity of the screw:0.015mm

7.The surface hard chromium plating hardness after nitrogenation≥900HV

8.Depth of double alloys:0.8-2.0mm

Used for granulation ,PP,PE,PA,PC,ABS,AS etc

Our Factory

Our package

About JIAWEI:

- We have an experience of more than 20 year of manufacturing and designing Plastic machines, varied Screws and Barrels and spares. We concentrate on improving quality, updating design and enhancing service.

- Screws Barrels for Injection, Extrusion, and Blow Molding applications; relevant accessories; plastic machinery.

- Located in China's Screw Town - Jintang Town in Zhoushan City, near toNingboPortandShanghaiPort.

- Global sales network reaching South America, Eastern Europe, Southeast Asia, Africa, Oceania and the Middle East.

- We assure the customer benefits. We provide competitive price, We Emphasis on Cooperation.

Our screw and barrel can ensure high performance and low energy consumption of extruder and Injection molding machine.

We can supply professional screw and barrel to your order!

| Packaging Detail:wrapped by film & wooden case |

| Delivery Detail:25-30 days after order confirmed |