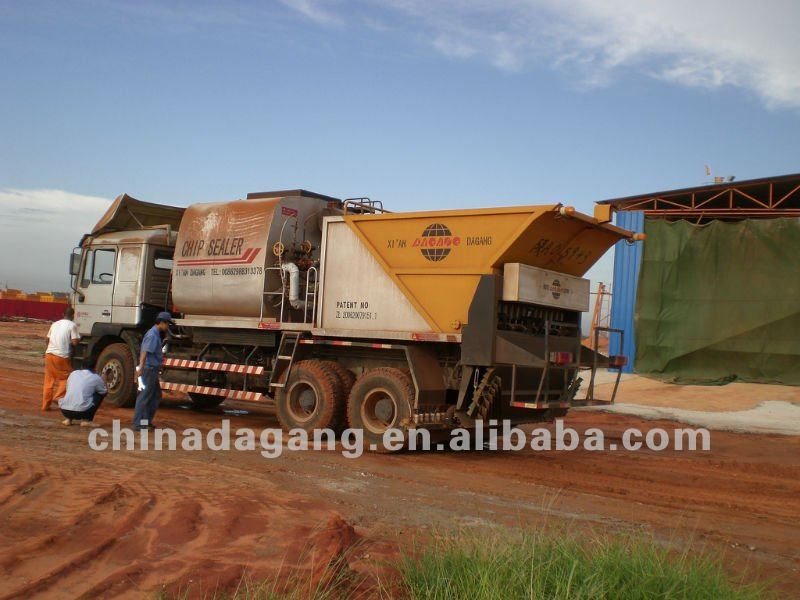

CHIP SEALER

| Condition:New | Place of Origin:Shaanxi China (Mainland) | Brand Name:DAGANG | Model Number:DGL5311TFC |

ⅠOverview

Dagang manufactured DGL5311TFC Rubber Asphalt Chip Sealer can be used for paving underlying seal coat and surface seal coat, paving wearing course for new or old road surface, spreading in layers during road consctrution, separately spreading asphalt and chippings under special conditions. Which is available for various different grade road.

ⅡProduct Characters

a) All operations can be performed by one operator in Cab

b) Asphalt spraying rate is controlled by computer which is independent of the truck speed.

c) Chipping spreading rate is controlled by computer which is independent of the truck speed.

d) An intelligent linkage between asphalt and chippings spreading systems.

e) Asphalt valves fully automatic.

f) Available for various kinds of asphalt including asphalt rubber, raw asphalt, asphalt emulsion.

g) Spraying pipe can be folded and lifted by hydraulic system.

h) Equipped with advanced double U type heating system, unique heat exchange system, circulating and insulation system, to insure the asphalt pipelines and nozzles “not to be blocked” and “not need to be washed by diesel oil”.

i) With advanced mixing device which effectively avoids the segregation precipitation of rubber grain.

j) Uniquely combined aggregate bin with lower height, which is advantaged to work under viaduct and tunnel.

k) Control system introduces modularization design, has very reliable working performance and convenient troubleshooting.

l) Rador speed measurement.

m) Function of heating and insulation during driving.

n) Equipped with thermal oil heating and insulation hand spray bar which is able to spray on the special places on the road.

o) To realize fully three-overlapping asphalt spraying at two sides which improved the sealing quality.

p) Chip spreading plate angle of inclination is adjustable, which is available for needs of adjustment during a different slope construction.

q) Chip spreading plate ends edge is adjustable, which is available for needs of adjustment during a different roadside construction.

r) Opening and closing of the doors of aggregate bin are controlled by pneumatic control valve. Every door of aggregate bin and nozzle can be controlled separately.

s) The combined aggregate bin can be lifted at appropriate automatically by level gage to realize the continuous supply of aggregate.

t) Equipped with Monitoring System, working specifications can be displayed on display screen at any time.

u) With functions of suck-in and discharge, can realize the asphalt loading and discharging.

Main Performance Parameter

No | Parameter | Unit | Standard | Remark |

1 | Displacement and Power of Engine | ml/kW | 9726/213 | |

2 | Total Mass | kg | 31000 | |

3 | Chipping size | mm | 3-25 | |

4 | Max. Sealing Width | mm | 4200 | Difference is 262 |

5 | Working Speed | km/h | 3-6 | |

6 | Spraying Rate | kg/ m2 | 0.5-3 | |

7 | Chip Spreading Rate | L/m2 | 2-22 | |

8 | Asphalt Tank Capacity | L | 8000 | |

9 | Aggregate Bin Capacity | m3 | 13.5 3.5 | |

10 | Overall Dimension | mm | 10300×2500×3750 |

| Packaging Detail:nude package |

| Delivery Detail:45 days |