China Best bricks factory machine Price

| Condition:New | Type:fired brick making machine | Brick Raw Material:clay, shale, coal gangue, coal ash | Processing:Brick Molding Machine |

| Method:Vacuum Extruder | Automatic:Yes | Capacity:12000-18000standard block/hr | Place of Origin:Shandong China (Mainland) |

| Brand Name:GOBULL | Model Number:JKY50/50-35 | Voltage:380V | Power:132+75+5.5(15) |

| Certification:ISO9001:2008 | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | extruder:full steel |

| Weight:16t | Performance:reliable and durable | After-sale service:life time |

China professional bricks factory machine manufacturer, not only supply brick factory machie but also turnkey project, we also have own brick factory, welcome you visit our brick machinery company and brick company!

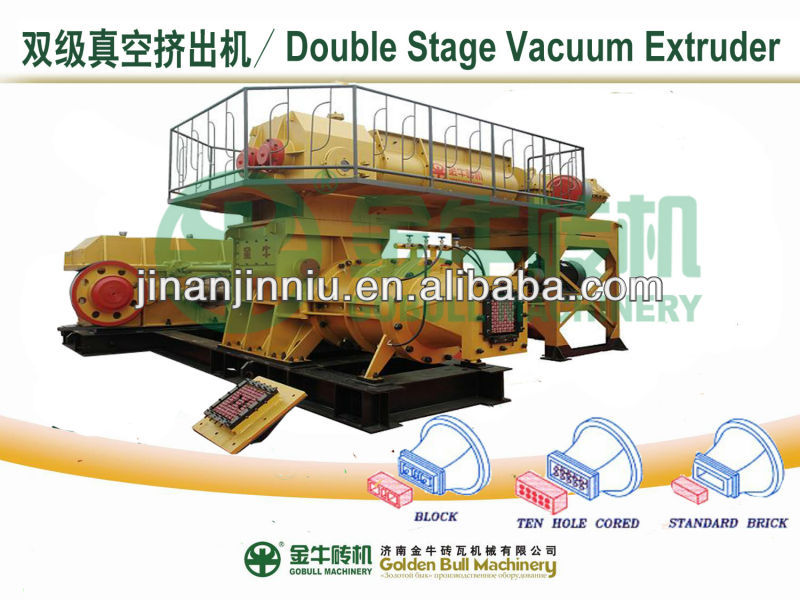

Double Stage Vaccum Extruder(bricks factory machine)

Product description:"Golden Bull brand" series double stage vacuum extruder is the new brick making equipment designed and manufactured by our factory through several researches and use of domestic and international advanced experience. The main frame is welded by using high-quality steel, and has the features of rational structure, solid and durable properties, strong adaptability, low energy consumption, high efficiency, and easy maintenance and so on. It is the ideal equipment for production of various hollow brick, shale, coal gangue and coal ash.

bricks factory machine Main technical parameters:

| specificiation | ( chinese standard) block/hr | MPa | Kw |

| JKY75/75-35 | 16000-28000 | ||

| JKY60/60-40 | 13000-26000 | ≤0.092 | 250+110 |

| JKY55/55-40 | 11000-25000 | 160+75 | |

| JKY55/55-35 | 13000-25000 | 160+75 | |

| JKY50/50-40 | 10000-18000 | 132+75 | |

| JKY50/50-35 | 12000-18000 | 132+75 | |

| JKY45/45-35 | 7000-13000 | 110+75 |

Note:the shown value of production capacity is in connection with the actual nature of raw materials; power with * is the power of vacuum pump motor; power of gas source is not included.

Advantages:all-steel welded structure, floating spindle, wear-resistant high-chromium alloy hub. The personalized rimer which is newly designed according to the nature of raw materials has the features of high output, low power and excellent performance.

Double stage vacuum extruder(bricks factory machine)

Before-sale services:

(1)Guide customers to choose the best appliable machine type; provide the advanced, energy-saving and practical technological process,

(2) We are responsible for the process chart and design.

Sale services:

(1)Products must be inspected strictly before selling;

(2)In accordance with the agreements stipulated in the contract,

(3)We will organize delivery.

After-sale services:

(1)Our company will send professional engineers to guide with device installation, debugging and training operators until customers are fully satisfied. Moreover, we will design and manufacture products, according to the special requirements of customers.

(2)The quality guarantee period for machines is one year except the wearing parts.

bricks factory machine in the production line

Brick cutting machine in bricks factory

the opening part of the extruder

Thereamerof the extruder

tunnel kiln construction

the basic process flow for reference only

| Packaging Detail:Seaworthy packing |

| Delivery Detail:30days after receive the deposit |