Chemical Glass Reactor

| Condition:New | Automatic Grade:Automatic | Type:Reaction Kettle | Place of Origin:Henan China (Mainland) |

| Brand Name:Boke | Model Number:BK | Voltage:220 | Weight:71kg |

| min temperature:-60°C | max temperature:300°C |

Jacketed Glass Reactor

Video of jacket/jacked glass reactor: http://v.youku.com/v_show/id_XMzkyNzE1Njg4.html

This jacketed glass reactor can be used todo high temperature experiment(max temperature is250°C),as well aslow temperature experiment(min temperature is-60°C) andvacuum tests.It is an ideal equipment formodern chemistry small and medium-sized experiment,bio-pharmaceuticals and new materials synthesis.

Furthermore,the design of this reactor is unique,which can guarantee experiments ofmore convenient and safer.

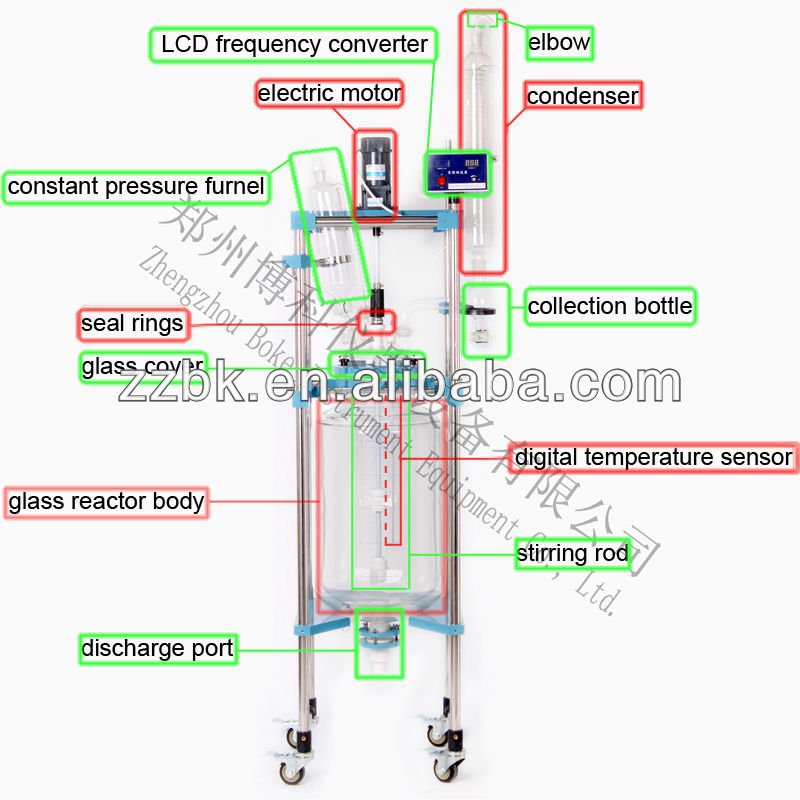

The structure of the 100L jacketed glass reactor:

Detail structure and information:

There are two different types of conveter:

Aboutthe sealing of the stirring rod,it istitanium alloy mechanical sealing,which is morestability,and the rusting is disappearance.There isa fluororubber sealbetween titanium alloy circle and PTFE.Each glass reactor must through the strict tests before leaving factory,the sealing performance is0.098Mpa.

The core part is theglass reactor body.Our glass reactor is made ofGG3.3 high boron silicon glass,it isdouble glass design,inner into reaction menstruum do stirring reaction,interlayer can be passed different kinds of liquid(such as hot water,hot oil or cryoprotectants) todo cycle heating or cooling reaction.Setting thermostat conditions,it can be usedin require atmospheric or negative pressure conditionsto conducte stirring response anddo reaction solution reflux and distillation.

Furthermore,the warranty for our glass reactor body is one year,dear customer could use it with no anxiety.

If the liquid you poul into the glass reactor is dangerous,such asstrong acid and alkali, or you need onethermal-insulation equipmentfor the glass reactor body,you could choosethe safety insulation cover,which cost is USD78.

Aboutthe discharge port,we usealuminium ring flange for fixing.There isno dead cornerin the container,soit is easy to outlet the reaction material.

If you needpump vacuumand heat liquidthat circulate in the interlayer,you could choose other two equipments:water circulating vacuum pump and high temperature circulator.

The complete plant:

Operating principle:

1 The inner layer is used toinject reaction material.

2 Theconstant temperature fluid,which be injectted in the jacketed glass,can be replaced byhot solutionorcooling liquid,to do cycle heating or cooling reaction.

3The reaction material can be stirredby stirring rod.

4The reaction process happened in the vessel.

5 Theevaporation and backflow of reaction materialcan be controlled.

6 When the reaction is completed,the reaction material can be released from the discharge port,which is in the bottom of the reactor.The operation is quite convenient.

Features:

1 All of the glass adoptsPyrex,which can ensure good chemical and physical properties.

2 Ifhot oilcycles through the jacketed glass,heating experimentscould be done.On the contrary,low temperature experimentscan be done if the circulatedfluid is cold.

3The heat of reactioncould be taken away quickly through water,which cycling in the jacketed glass.

4 Large mouth design makes iteasy to clean,standard mouth makes theassembly and backflowcould be chose.

5 It can be used asdistillation syntheses device.

6Titanium alloy mechanical sealing.So the sealing is more stability,the stirring is more evenly,the rusting is disappearance.There isa fluororubber sealbetween titanium alloy circle and PTFE.Each glass reactor must through the strict tests before leaving factory,the sealing performance is0.098Mpa.

7 The temperature is measured byPT100 electronic.

8LCD displaymakes it is easier and more convenient to measure temperature.

Technical Details:

| Model | BK-100L | |||

| Power | 90W(gear motor) | |||

| Stirring speed | 20~600r/min | |||

| Material capacity | 100L | |||

| Inside and Outside Glass Cylinder Diameter | 245*260mm | |||

| Dimension | 50*41*160 cm | |||

| Packing Size | 58*51*136 cm | |||

| Packing Weight | 71 kg | |||

| Power supply (V/Hz) | 220V/110V 50Hz/60Hz | |||

| Packaging Detail:standard packing |

| Delivery Detail:7-15days |