chemical agitator mixer

| Place of Origin:Guangdong China (Mainland) | Brand Name:NOSEN | Model Number:RN-020~750 | Mixer Type Agitator:Application Liquid |

Chemical agitator mixer

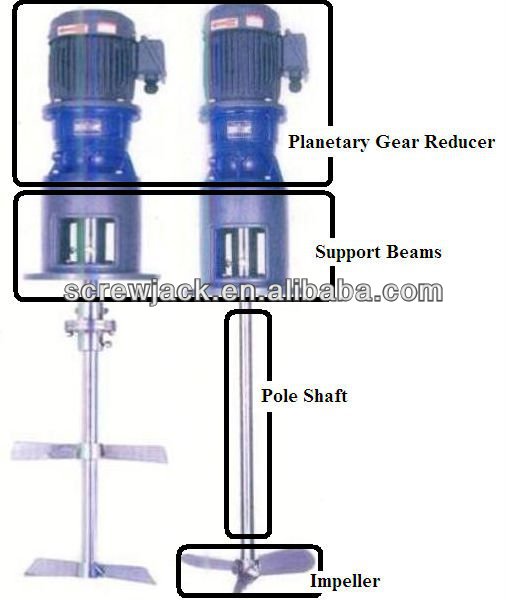

NOSEN Vertical Agitator Main Structure includes motor,speed reducer and supporting base.The Mixer includes shaft coupling,pole shaft and blades etc. Bellow is the main structures simple descriptions.

Motor:to select a motor,except for the base requirements of the input power,the key is to be careful for the installation environment, including indoor and outdoor point of the mixing material to clearly identify it is indoor type or outdoor type.Our engineers will supply the most professional and the safest selection according to different environments.

Speed Reducer:As many types of speed reducer,their structures and efficiences are quite different as well as the pricing. The installation and spaces could also be restricted, NOSEN supply Taiwan SANYA Planetary Gear Speed Reducer,to ensure vertical agitator with first-class quality.

Supporting Base:Because fierce dynamic loading generated by the mixing of the fluid,the motion stability and life of the vertical agitator is determined by the structure of the supporting base. Rotating speed,viscosity and capacity etc are the factors to be considered. NOSEN will provide different models following clients requirements. All supporting base are precision machined to increase their operation stability.According to different environments,we will select the most suitable materials for supporting base.

Shaft Coupling:According pole shaft length, we will select different type flange shaft coupling for its solid structure that will connect the mixer with mixing machine firmly and in a straight line.

Pole Shaft:At present, NOSEN pole shaft materials is SS304 or SS316, is also for customization.

Mixing Blade:We have two kinds of propellers type for selection,blade paddles and spiral blade.Usually, SS304 or SS316 are selected,is also for customization.

Notes on operation:

* Check the rated voltage and loading current on the nameplate of the electric motor before turning on the power and confirm the input voltage is correct and whether the overload relay is equipped.

* It is strictly prohibited to operate before the blades fully immerse in the liquid to avoid danger and damage to the equipment.

* The fixing base of the equipment should have enough rigidity. A working environment that is free of resonant impact is better.

* Confirm all base bolts and screws are tightened before turn on the power of the mixing machine.

* If the equipment exhibits abnormal noises, temperature rise and swaying after power on, stop the operation immediately and check again.

* Whether the temperature of electric motor is abnormal or not? When the loading increases to a normal condition, please check if the current exceeds the rated current. If overload found, please replace with the one with larger power.

Features:

Electricity systems: 110~440VAC,50/60Hz,1/3 Phases

Power:0.25~25 hp

Revolutions:15~1500 rpm

Pole shaft diameter:20~70 mm

Propeller diameter:100~1500 mm

Application:

Chemical industrial

Food processing

Agricalture

| Packaging Detail:plywood box or according to customers needed |

| Delivery Detail:depends on quantities |