Cheap Energy Saving Wood Chips Dryer

| Condition:New | Type:Drum Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:Libo |

| Model Number:wood chips dryer 1.0*10 | Voltage:380v | Power(W):5.5kw | Dimension(L*W*H):12*2.2*2.5m |

| Weight:7.5t | Certification:as required | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

| colour:customizable | rotational speed:6.73r/min | volume:7.85m³ | diameter:1m |

| length:10m | gradient:3-5° |

Cheap Energy SavingWood ChipsDryer

Wood Chips Dryeris suitable for drying granules with heavy specific gravity in chenmical industry, mine industry,metallurgy industry etc

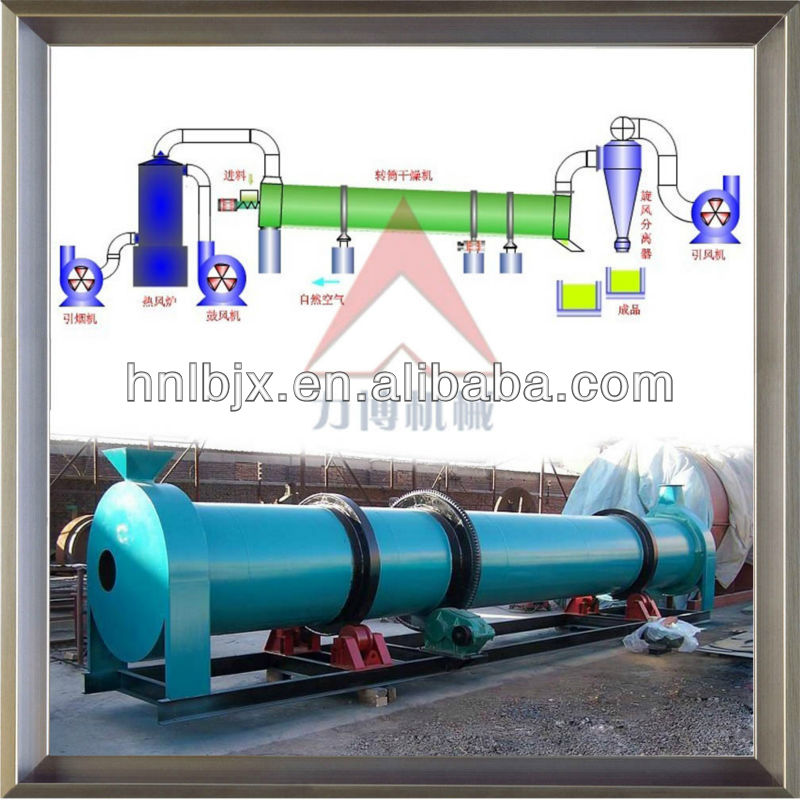

Structure of Wood ChipsDryer

1 hopper

2 dosing machine

3 incoming material feeder

4 heating resources

5 drying roller

6 discharge feeder

7 cyclone

8 draft fan

9 belt conveyor

10 variable motor

11 reduction gear

Wood Chips Dryer Advantages

1.reasonable structure

2.high capacity

3.low consumption

4.cheap

5.europe standard

6.Chinese supplier, China factory

Working Principle of Wood ChipsDryer

1 The material was sent to hopper by belt conveyor or bucket elevator and then by the feeding machine of hopper through charging pipe into the feeding side.

2 The slope of feeding pipeline fromrotarydryershould bigger than the materials' natural dip angle, in order to sand smoothly flow into the dryer machine.

3 The drum ofrotarydryeris a rotary drum which is slightly obliquely with the horizontal line. Add the materials from the higher side, heating body goes into the lower end, form countercurrent contact with materials, also exists the heat body and materials together concurrent flow into the barrel. Along with the cylinder rotating, the materials move to the lower end by gravity.

4 During the moving process ofrotarydryer, wet materials in the cylinder directly or indirectly got heat from the heating body, make wet materials to dry, then in the discharging end the materials were sent out by belt conveyor or screw conveyor.

Main Technical Parameters ofWood ChipsDryer

| type | transfers barrel diam(mm) | transfers barrel length(m) | gradient(°) | rotational speed(r/min) | weight(t) | power(kw) | volume(m³) |

| Φ0.6*8 | Φ600 | 8 | 3°-5° | 8 | 5.1 | 4 | 2.26 |

| Φ0.8*10 | Φ800 | 10 | 3°-5° | 7.2 | 6.9 | 4 | 5.02 |

| Φ1.0*10 | Φ1000 | 10 | 3°-5° | 6.73 | 7.5 | 5.5 | 7.85 |

| Φ1.2*12 | Φ1200 | 12 | 3°-5° | 5.8 | 13.1 | 11 | 13.31 |

| Φ1.5*12 | Φ1500 | 12 | 3°-5° | 4.8 | 22.3 | 15 | 21.2 |

| Φ1.8*14 | Φ1800 | 14 | 3°-5° | 3.2 | 45.8 | 30 | 48.22 |

| Φ2.2*18 | Φ2200 | 18 | 3°-5° | 3 | 50.3 | 37 | 70.43 |

| Φ2.4*20 | Φ2400 | 20 | 3°-5° | 2.83 | 78.4 | 45 | 90.43 |

| Φ2.8*24 | Φ2800 | 24 | 3°-5° | 2.59 | 97 | 75 | 147.8 |

| Packaging Detail:Export standard |

| Delivery Detail:15-30 days |