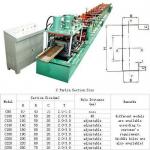

Changeable C/Z Purline roll forming Machine

| Type:Steel Frame & Purlin Machine | Place of Origin:Henan China (Mainland) | Brand Name:Anson | Coil Width:0-650mm |

| Suitable Coil Thickness:1.0-3.0mm | Suitable MaterialMaterial:Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel | Roll Station:18 Stations | Forming speed:10-15m/min |

| Material Thickness:1.0 -3.2 mm | Yield strength:350Mpa |

Feature:

Cantilever Type Adjustable Roll Former infinite varieties of "C" channels and Z channels within the parameter of the machine, without tool change. The product dimension changeover time can be as low as 10 min.

It is very easy to change one dimension of the web height ("h") or the leg length (l) of C or Z channels.

Switch C To Z: Only rotate some stands.

Change sizes for C Or Z: Press button on the machine, motorized to change the position of one side of rollers.

Change degree for Top flange of C: Rotate some stands

Work Flow:

De-coiling→Entry Guide→Leveling→Pre-Punching→Pre-Cutting Adjustable Rollformer→Straightening→→ Run Out Table

Equipment List

1. Hydraulic un-coiler

2. Entry Guide + Five(5)-Roll Leveler

3. Hydraulic Pre Punching Device

4. Hydraulic Pre Cutting Device

5. Cantilever Type Adjustable Roll Former (18 Roll Stations)

6. Strengthening Device

7. Run Out Table

8. Electric control system

9. Hydraulic station

Technical Parameters

(1) Max. Coil Width: 650mm

(2) Suitable Coil Thickness: 1.0-3.0mm

(3) Suitable Raw Material: Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel

(4) Yield strength: 350Mpa

(5) Roll Station: 18 Forming Stations

(6) The material of the roller: GCr15(Equal To 100Cr6 Bearing steel) HRC58-60

(7) Line speed: Forming speed:10-15m/min

Work Flow:

De-coiling→Entry Guide→Leveling→Pre-Punching→Pre-Cutting Adjustable Rollformer→Straightening→→ Run Out Table

.

profile for the machine

Machine Components

(1) Manual Un-coiler 1 set

(2) Leveling Device 1 set

(3) Roll-Forming M/C 1 set

(4) Hydraulic Cutting(10 cutter) 1 set

(5) PLC Control System 1 set

(6) Product Rack (un-powered) 1 set

(2)Roll Forming Machine: 13 steps to form; Material of Roller: GCr15, Voltage: 380V/50Hz, Main line speed: 0- 10m/min

(3)Hydraulic Cutting

Stop to cut, Post cut and no waste the material

Cutting tool material: Cr12, Include 5 pairs of shears.

The lengh tolerance is ±2.0 mm

Hydraulic cutting machine has features: Stop to cut, Post cut and no waste the material, Cutting tool material: Cr12, Include 5 pairs of shears. The lengh tolerance is ±2.0 mm

(4) PLC Control System controls the quantity, which has the features of length automatically and LCD screen.

(5)Product Rack (Un-powered), Two piece total 6 meters

| Packaging Detail:Main machine body and decoiler is loader naked , some spare parts are in wooden case |

| Delivery Detail:60 days after receipt the payment |