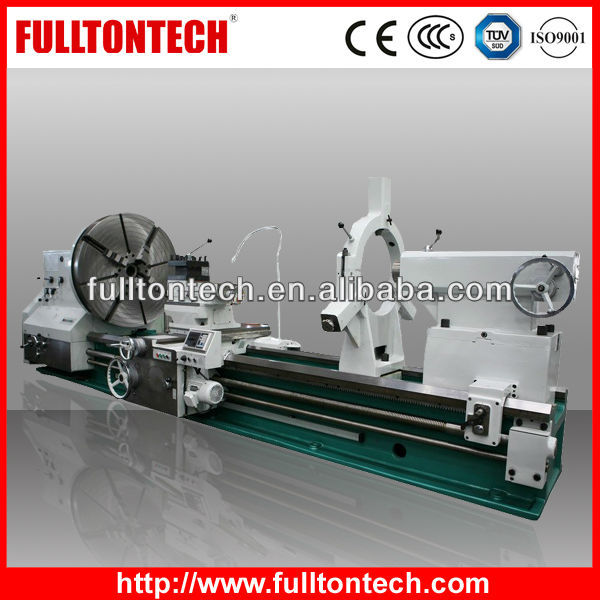

CF61100 Horizontal Lathe Machine

| Condition:New | Type:Horizontal,Horizontal Lathe Machine | CNC or Not:Normal | Automatic Grade:Manual |

| Max. Swing Diameter:1000mm | Place of Origin:Tianjin China (Mainland) | Brand Name:FULLTONTECH | Model Number:CF61100 |

| Voltage:According to client's site voltage | Power(W):22 KW | Dimension(L*W*H):Section of tool shank: 45x45 | Weight:Max. weight of workpiece: 8 tons |

| Certification:CE Certificate; ISO9001:2008 | After-sales Service Provided:Engineers available to service machinery overseas | material:high grade cast iron | colour:any colour |

| transportation method:seaway or railway | guarantee:13 months afer shipment | usage range:turning;grooving;end-facing | package:fumigated wood box |

| dilivery time:45-60 days | payment:L/C;T/T | trade term:FOB, CIF prefered |

Conventional Horizontal Lathe Machine

Model CF61100

1.Main specification

| Main Specifications | CF61100 |

| Max. swing diameter over bed | 1000mm |

| Max. swing diameter over carriage | 630mm |

| Max. load of workpiece between centers | 8ton |

| Width of guideways on bed | 755mm |

| Guideway type | Two guideways |

| Distance between centers | 1000 to 10000 mm |

| Spindle bore diameter | 100mm |

| Taper of spindle nose | 1:20 |

| Spindle speed steps | Forward12 Reverse12 |

| Range of spindle speed | 4.25-192rpm |

| Range of metric threads | 46kinds 1-224mm |

| Range of whitworth threads | 46kinds 28-1t.p.i |

| Range of module threads | 37kinds 0.25-56mm |

| Section of tool shank | 45×45mm |

| Max. travel of top slide | 350mm |

| Diameter of tailstock quill | 140mm |

| Travel of tailstock quioll | 300mm |

| Tailstock quill taper(Morse) | Morse No.6 |

| Main motor power | 22Kw |

2. Pictures

2.1 Pictures of horizontal lathe machine details:

2.2 Pictures of horizontal lathe machine packing and loading

2.3 Pictures of horizontal lathe machine commissioning:

2.4 Pictures of other products from our product line:

3. More details of this horizontal lathe machine:

Machine bed:Due to the mixing arrangement of V-flat guideways, the machine bed is endowed with an excellent technology. With 1100mm in width, 710mm in height, and box shape canting pull plate structure of high rigidity, the bed has a great feature of stability and bearing capacity. Moreover, the entire bed is in a casting structure and reasonable stiffened plate arrangement internally. The guideways adopt the middle frequency quenching-grinding process which makes them have a very good hardness. Technological measures will be taken, such as sticking crawl-preventing guideway plate on the surface of slide guideways to make the dynamic features such as rigidity of feed system and friction damping coefficient be in their best status, thus avoiding occurrence of low speed crawl.

ChuckThe standard configuration of machine tool of the series is manual-operated chucks with diameters of 1250,1400,1600,1800 mm. Chucks are made of casting steel materials with static balance technology.

Feed box & Slide boxThe boxes are driven by electromagnetic clutches of simple structure and high reliability, which makes it very convenient for maintenance. Meanwhile, the cross handle switches also provide us a compatible operation.

Tool rest of the saddle

For each series, it is endowed with the function of automatic feed. With the structure of double layer compound rest whose diameter is over 1400mm, it can easily realized the longitudinal and cross feed. The four-working-position rest can rapidly change tools and clamps them accordingly.TailstockThe tailstock adopts a structure with high bearing capacity, and the handles equipped on the side are very easy for operation. There are also active centers inside. Besides the feature of high rigidity and rotating accuracy, the tailstock is equipped with rotating and fixing conversion devices. The motor-driven tailstock, whose sleeve diameter is 240mm and stroke is 250mm, also has the backward preventing security mechanism and sleeve force-measuring mechanism.

Hydraulic systemThe system can be effectively and rapidly performed with hydraulic braking. For lubrication, it is the same system used in machine head. Main hydraulic elements are all produced by Taiwan COMPASS of good quality and high working reliability.

Cooling and chip disposing systemThe standard configuration of the machine will adopts chip pan for chip disposal. The cooling box will be separated from the main set to avoid the machine accuracy being affected by heat caused by cutting. The system will adopt home-made cooling pump, and the cooling box will be installed in trench.

Company Introduction

Fullton Machinery Co., Ltd headquartered in Dalian, one of the largest seaport cities of China, Fullton Machinery Co., Ltd is one of the leading machinery group specializing in producing heavy duty lathe machine, it has four factories in China which mainly produce vertical lathe machines, heavy-duty horizontal lathe machines and boring mills, both conventional and CNC types.

In reliance of the advantage in product range, reliable quality, technical back-up and after-sales networks over 30 countries worldwide and fullton machinery Co., Ltd has become the well-known Chinese brand name overseas.

Fullton Machinery would like to offer its best lathe machines with best solution, and build itself as the bridge and window for both overseas and domestic enterprises and customers.

Combined with outstanding productivity and service, our customers enjoy a significant market advantage. We believe in achieving excellence and that there is always room to improve. Fullton machinery Co., Ltd consistently strides ahead of the pack in precision, innovation, service excellence, and a practical, sustainable approach to business.

| Packaging Detail:Dismantled into fumigated wood cases and loaded into containers. |

| Delivery Detail:2-3 months |

![[Handy-Age]-Universal Tool Cutter & Grinder( MW2000-014)](http://www.machineto.com/img/thumb/10/12/79/10127975.jpg)