ceramic coating machine (plasma spray machine,powder coating)

| Condition:New | Type:Coating Production Line | Substrate:Ceramic and metal powder with high melting point | Coating:Powder Coating |

| Place of Origin:Guangdong China (Mainland) | Brand Name:SX | Model Number:plasma spray machine | Voltage:220 |

| Power(W):80KG | Dimension(L*W*H):2.5M3 | Weight:350KG | Certification:ISO9001 |

| Warranty:3 years | After-sales Service Provided:Engineers available to service machinery overseas | get accurate coating:high strength | low porosity:low price |

| powder coating plate:powder coating oven/machine/ line | key:ceramic coating |

Introduction of ceramic coating machine

(plasma spray machine,powder coating)

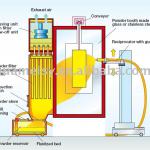

1.Brief Induction of ceramic coating machine (plasma spray machine,powder coating)hightemperatureresistingcoatingusing argon, nitrogen, hydrogen as working gas, the ionizing hightemperature melt the powder into plasma forming gas, expands and is accelerated through a shaped nozzle, creating velocities up to MACH 2. Temperatures in the arc zone approach 36,000°F (20,000°K)

2.Characteristics of ceramic coating machine (plasma spray machine,powder coating)(hightemperatureesistingcoatingcan spray all kind of Metal powder, such as Ceramic powder ( Chrome oxide, Titanium oxide, Aluminum oxide, aluminum titanium oxide, Zirconium oxide powder, etc.), Alloy powder (WC-Co, Cr3C2-NiCr), Chrome, Titanium, Silicon powder, etc.

(2) Inert gas can be used as working medium to reduce the oxidation of spraying particles.

(3) The coating can get high bond strength, low porosity. You can get accurate coating by controlling technological parameter.

3.Applications of ceramic coating machine (plasma spray machine,powder coating)(1) Provide protection against high temperatures, corrosion, erosion, wear-resisting effect,prolong lifetime.

(2) Change appearance, electrical or tribological properties of the surface, replace worn material

(3) Sprayed on substrates of various shapes and removed, free-standing parts in the form of plates, tubes, shells, etc.

(4) Powder processing (spheroidization, homogenization, modification of chemistry, etc.)

4. Composition of ceramic coating machine (plasma spray machine,powder coating)(1) high power supply.

(2) transfer box .

(3) intellectualized control cabinet.

(4) double cylinder powder feeder.

(5) plasma spray gun

(6) industrial chiller with high heat exchange polyethylene coating efficiency

5. Other main thermal spraying equipments and service:

(1) Vacuum plasma spray machine

(2) Thermal spray coating services

(3) HVOF spray equipment

(4) Plasma spray equipment

(5) Arc spray equipment

(6) Sputter Target Produce Equipment and technology

(7) Industrial water chillers

(8) Precious metal vacuum coating equipment

(9) Cooker magnetism and thermal conduction coating spraying production line

(10) Electro Brush Plating Equipment

(11) High power flame plastic spray equipment

(12) Arc spray wires (Zinc wire, Aluminum wire, copper wire, NiAl alloy wire, brass wire, etc)

(13) Thermal spray powder (Al2O3, Cr2O3, TiO2, ZrO2, WC-Co, CrCo-NiCr, etc)

Some qualifications as follows,

Some clients has dealed with our factory.

Dear,please kindly contact me with the following question,our group will give you the best solution ASAP.

1. What kind of products will you want to spray ? --- Could you provide some pictures?

2. Which meterial will you want to use? wire or powder?(zinc wire,alumium wire,stainless wire ,copper wire ,gold wire ,tugesten carbide power ,ceramic powder and so on)

3. Which effect will you want to get ? High temperature resisting ,wear resisting or anticorrosion ,reparing work or others?

4. Do you have any other technical requirements? the more the better.

Contact information, (Name,Ms Emmy)

| Items | Details | Items | Details |

| Cell phone | +86 15913165959 | TradeManager | cn1001156364 |

| skype | emmy168888 | Yahoo messenger | emmy168888 at Yahoo.com |

| 1984806933 | MSN | emmy168888 at hotmail.com | |

| emmy168888 at Yahoo.com |

remark,at means @

ceramic coating machine (plasma spray machine,powder coating)

| Packaging Detail:Iron box or in wooden casesceramic coating machine (plasma spray machine,powder coating) |

| Delivery Detail:within 18 days |