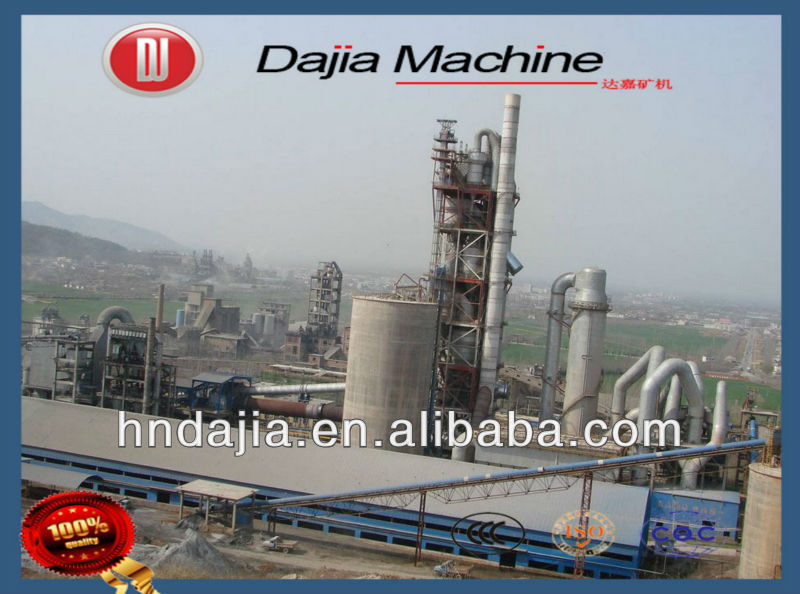

Cement Kiln/Rotary Kiln/Poland Cement Burining Kiln

| Place of Origin:Henan China (Mainland) | Brand Name:Dajia | Condition:New | After-sales Service Provided:Engineers available to service machinery overseas |

Manufacturing - the cement kiln

Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two. The axis is inclined at a slight angle, the end with the burner being lower.

The rotation causes the raw meal to gradually pass along from where it enters at the cool end, to the hot end where it eventually drops out and cools. contact with me via skype:gary102884 if need cement plant. They were introduced in the 1890s and became widespread in the early part of the 20th century and were a great improvement on the earlier shaft kilns, giving continuous production and a more uniform product in larger quantities.

The original rotary cement kilns were called 'wet process' kilns. In their basic form they were relatively simple compared with modern developments. The raw meal was supplied at ambient temperature in the form of a slurry.

A wet process kiln may be up to 200m long and 6m in diameter. It has to be long because a lot of water has to be evaporated and the process of heat transfer is not very efficient.

The slurry may contain about 40% water. This takes a lot of energy to evaporate and various developments of the wet process were aimed at reducing the water content of the raw meal. An example of this is the 'filter press' (imagine a musical accordion 10-20 metres long and several metres across) - such adaptions were described as 'semi-wet' processes.

The wet process has survived for over a century because many raw materials are suited to blending as a slurry. Also, for many years, it was technically difficult to get dry powders to blend adequately.

Quite a few wet process kilns are still in operation, usually now with higher-tech bits bolted on. However, new cement kilns are of the 'dry process' type.

Our Dajia mining company is mainly produce:

Cement plant: capacity 100TPD----6000TPD

Rotary Kiln: diameter from 1.6m to 4.8m; length from 28m to 80m

Crushing machinery: crusher, impact crusher, cone crusher, vertical crusher, ball mill, rod mill

.......

Contact with Gary for much more detials if need our machine.

| Packaging Detail:negociated, caused the cement plant included many machineries. |

| Delivery Detail:30 days |