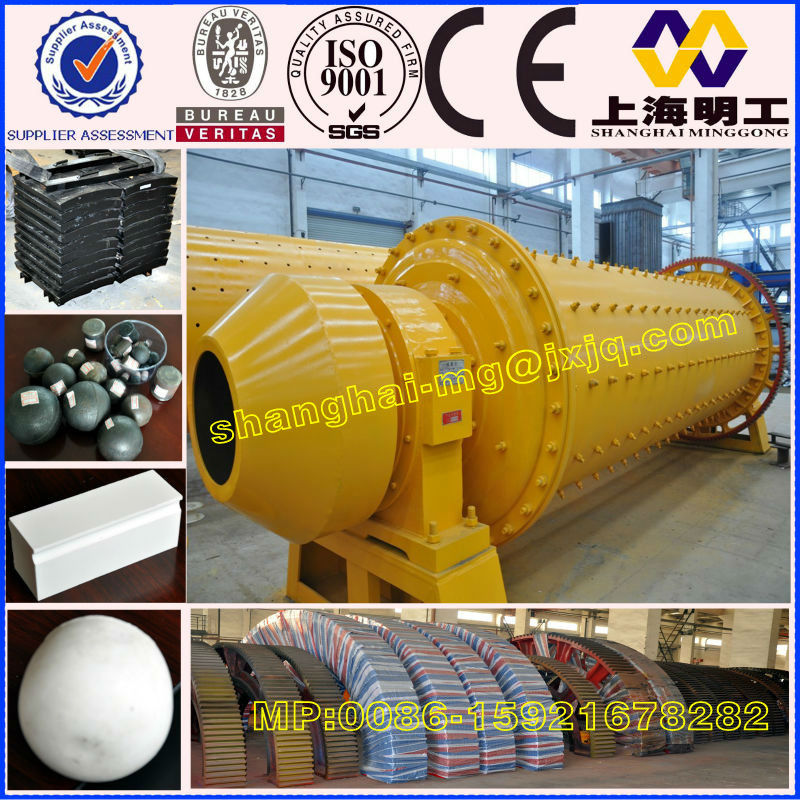

Cement Grinding Mill Plant/Cement Grinding Ball Mill/Cement Grinding Mill Process Plant

| Condition:New | Type:Ball Mill | Motor Type:ANY | Power(W):570kw |

| Capacity(t/h):0.5-300 | Place of Origin:Shanghai China (Mainland) | Brand Name:Minggong | Model Number:All Model |

| Dimension(L*W*H):according to the capacity | Weight:79t | Certification:CE ISO9001:2000 | Warranty:1YEAR |

| After-sales Service Provided:Overseas service center available | shell size dia*length:900*900mm-4200*1500 | efficiency volume:4.0m2 | capacity:0.5-300T/H |

| power:18.5-1800kw | balls weight:4.6-280T | speed:39-17/min | working life:normal life span |

| discharge scope:0.8-0.074mm | installation:under our engineer's guide | keyword:cement grinding mill plant/cement grinding ball mill |

Ball Mill

Ball mill application:

ball millis the key equipment for re-crushing, ball mill widely used for dry or wet powder grinding operation of ore grinding before dressing ferrous and non-ferrous metal, raw material or finished product of cement, chemical industry, novel construction material, refractory material, etc. ball mill is composed by feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control).The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which cement grinding mill plant/cement grinding ball mill/cement grinding mill process

General working principle of ball mill :

This machine is a skeleton pattern ball mill with horizontal cylindrical turning gear, driving by outer gear and two hoppers. The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment. The hopper has ladder sheathing or corrugated sheathing with steel balls inside, which will fall under the effect of centrifugal force by barrel turning to ram hard and grind material. After the kibbling in the first hopper, by monolayer partition panel, the material will enter the second hopper, which has plane scale board with steel ball inside to grind material. The powder material will be discharged from the grid plate to finish the grinding.

cement grinding mill plant/cement grinding ball mill/cement grinding mill process

ball mill types:

Dry or wet ball mill will be optional according to material and ore-discharging mode.

Wet Ball Mill’s Working Principle:

ball mill is a horizontal drum-like rotary unit, ball mill's outside is driven along the gear, inside the drum is medium (steel ball),material is fed through the feeding end of the drum, by following the rotation of the drum, the medium falls down after being lifted to a certain height by the centrifugal force from drum movement, heavily bang on the material due to irregular slide and rolling. Grinding thus comes into being among the medium, material and drum, so as to grind the material. The material is continuously fed, dynamic granularity level difference is thus occurred between the feeding and discharging ends, fine material flows out of the drum slowly and gradually, grinding

cement grinding mill plant/cement grinding ball mill/cement grinding mill process

| Ball Mill | Materail |

| 1 Feeding Device | ZG270-500 |

| 2 Bearing For Main Shaft | 40Cr |

| 3 Feeding Cover | ZGMn13 |

| 4 Fan-Shaped Liner | ZGMn13 |

| 5 Cylinder | Q235A |

| 6 Liner | ZGMn13 |

| 7 Gear Rim | 40Cr |

| 8 Discharging Cover | ZG270-500 |

ball mill parameters and model ,at same time we can special design as per our customers' requirement.

| Model | Cylinder rotary speed(r/min) | Loading ball weight(t) | Input size(mm) | Discharge size(mm) | Capacity(t/h) | Motor power (kw) | Weight (t) |

| Ø900×1800 | 39 | 1.5 | ≤20 | 0.075-0.89 | 0.8-2 | 18.5 | 4.6 |

| Ø900×3000 | 39 | 2.7 | ≤20 | 0.075-0.89 | 1~4 | 22 | 5.6 |

| Ø1200×4500 | 32 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Ø1500×3000 | 27 | 7.5 | ≤25 | 0.074-0.4 | 2~5 | 75 | 15.6 |

| Ø1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| Ø1830×3000 | 25 | 11 | ≤25 | 0.074-0.4 | 4~10 | 130 | 28 |

| Ø1830×6400 | 24 | 21 | ≤25 | 0.074-0.4 | 7~16 | 210 | 34 |

| Ø2100×3600 | 23 | 19 | ≤25 | 0.074-0.4 | 10-36 | 210 | 46 |

| Ø2200×4500 | 21 | 27 | ≤25 | 0.074-0.4 | 12~23 | 280 | 48.5 |

| Ø2200×6500 | 21 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

| Ø2200×7000 | 21 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

| Ø2200×7500 | 21 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

| Ø2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 18-45 | 320 | 65 |

| Ø2700×3600 | 21 | 39 | ≤25 | 0.074-0.4 | 19-75 | 400 | 83 |

| Ø2700×4500 | 20 | 48 | ≤25 | 0.074-0.4 | 22-85 | 430 | 89 |

| Ø3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | 29-140 | 800 | 137 |

| Ø3200×5400 | 18 | 81.6 | ≤25 | 0.074-0.4 | 30-180 | 800-1000 | 146 |

| Ø3600×4500 | 17 | 88 | ≤25 | 0.074-0.4 | 35-210 | 1000 | 190 |

| Ø3600×8500 | 17 | 144 | ≤25 | 0.074-0.4 | 45-260 | 1800 | 260 |

if any questions , pls feel free contact us , we will apprecite your contacting .

Skype ID: czmdanny2

| Contact Person : | Mr Danny Chen (Sales) |

| Address: | No.33 Shenxia Road, Malu Industrial Park, Jiading District, Shanghai, China |

| Zip/Postal: | 201818 |

| Telephone: | 0086-21-59515582 |

| Fax: | 0086-21-59515833 |

| Mobile: | 0086-13816543795 |

The process of manufacturing the product: The main machine in our plant: Our product saling to the whole world: |

The quality of product guaranteed by below process:

| Our good services: |

Cement Grinding Mill Plant/Cement Grinding Ball Mill/Cement Grinding Mill Process Plant

Cement Grinding Mill Plant/Cement Grinding Ball Mill/Cement Grinding Mill Process Plant

| Packaging Detail:cement grinding mill plant/cement grinding ball mill/cement grinding mill process with standarded exported packaging, bulk cargo |

| Delivery Detail:20days after receiving the deposit |