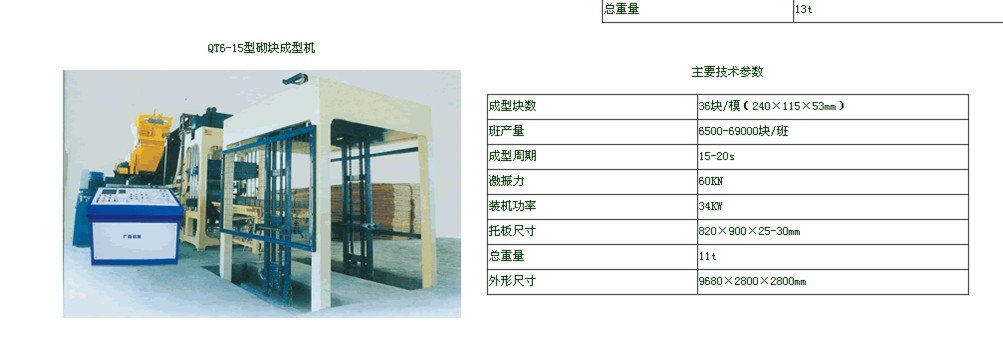

Cement and Concrete Block Brick Making Machine

Cement and Concrete Block Brick Making Machine:, 1.compact structure, 2.stable perfomance, 3.easy operation. - details see: https://www.machineto.com/cement-and-concrete-block-brick-making-machine-10076903

| Place of Origin:Henan China (Mainland) | Brand Name:Songling Tengda | Model Number:QT6-15 | TYPE:QT6-15 |

| Weight:13.5T | power:42KW | | |

Detailed Product Description

1. Low invest cost brick making machine

2. High efficiency and energy saving

3. Easy to operate

4..Stable quality

QT6-15 automaticBrick Making MachineLine making full use of effective vibration, transmit the vibration balanced to each part of the molding box, and improve the product’s density and the life of molding box.

QTJ6-15 automaticBrick Making MachineLine feeding in low-frequency, vibrating in high-frequency, and increasing in Head tanks, table and Mould vibrating together will make concrete fully liquefied and exhausted in 2-3 seconds to achieve high-density and high strength. Particularly be suitable for the production of high-strength block.

Send hopper is equipped with retro-swing cutting device, which could put material into the mold box equably

With the importing electrical and hydraulic system, the two systems can run basically without fault . The advanced random testing control system for remote can realize remote control and fault diagnosis. Dozens of different products’ adjustment of mechanical action, just under the menu options without the need of professionals; with the realization of human-computer dialogue, fully automatic operation

1,We offer first -rate products and service , if you want to find the most suitable partner in China we are will be your best choice .

The block making machine is global large productions capacity, which can be for different design of concrete block , paving stone and curb stone making by changing mould only .

2,Advanced vibrating technology from German assures to adjust and control the pressure and flow of every pipe conveniently. That enables us to produce the same high quality blocks with different raw materials.

3,The material distributing system mounted with multirow of stirring for scan quickly and evenly discharge the material into the mould box.

1.QT6-15 Main technical parametersDimension of host machine | 2900×2600×2900mm | Host machine power | 42KW | | Moulding area | 1280×600mm | Vibration force | 80KN | | Moulding period | 15-20S | Capacity | 102.3KVA | | The size of the pallet | 1350×780×25/30mm | Mixer model | JS750 | | Weight of the host machine | 13.5T | General water Consumption | 10T/every day | | Voltage | 380V | | |

2.Production capacity | Size(LxWxH) | Pcs/Mould | Pcs/ Hr | Pcs/ 8 Hr | m3/year | | 400X100X200 | 18 | 2700-4320 | 21600-34560 | 62208-82944 | | 400X150X200 | 15 | 2250-3600 | 18000-28800 | 77760-103680 | | 400X200X200 | 9 | 1350-2160 | 10800-17280 | 62208-82944 | | 400X250X200 | 6 | 900-1440 | 7200-11520 | 51840-69120 | | Paver:200X100X60 | 33 | 4550 | 36400 | | | Paver:200X163X60 | 15 | 2070 | 16560 | |

|

| Packaging Detail:International standard package,or as your request. |

| Delivery Detail:Two week workday or as your request |

Related Product for Cement and Concrete Block Brick Making Machine