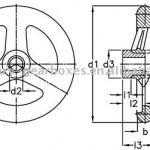

casting handwheel

| Place of Origin:Hebei China (Mainland) | Brand Name:aluoweier | Model Number:Each kind of specification | Material:Carbon steel,All kinds of carbon steel, alloy steel, stainless steel |

| Style:All kinds of valves handwheel | The product name:casting handwheel | On the surface:Spray paint and phosphating |

| 1.The product name | casting valve parts, casting handwheel |

| 2.Material | All kinds of carbon steel, alloy steel, stainless steel |

| 3.Process | Precision casting,lost wax casting,investment casting,The shell mould casting |

| 4.Certificate | ISO9001:2008 |

| 5.Professional skills | According to various drawings for production |

| 6.Machining Tolerance | ±0.005mm |

| 7.CNC machining equipments | Boring machine, line cutter, CNC lathe, CNC machining center, Grinding machine, drilling machine,N/A lathe, N/C lathe and all types of lathe |

| 8.Surface finish process | Surface rust prevention treatment,phosphating,Galvanized, chroming, baking, coating, |

| 9.Service | High quality, can meet your requirements |

| 10.Product | All kinds of valves parts and auto parts, as per customers’ requirement |

| 11.Technology available | Investment casting ,Die casting,CNC machining, forging,Water glass |

| 12.Advantage | Good quality and strict delivery time. |

1.Technology Silica sol binder

Lost wax

Investment casting process

2.Variety of materials Carbon steel

Alloy steel

Stainless steel

Ductile iron etc.

3. Standards ASTM, JIS

BS, DIN, EN, ISO

4. Capacities 2,000,000 pieces/Month

or 100Tons/Month

5. Field of applications Textile & sewing machine parts

Packaging & printing machine parts

Machinery parts

Auto parts(Valve roker)

Marine hardware parts

Lock parts

Electric tools parts

Hardware tools & other fields

6. Products advantages Casting dimensional accuracy can reach CT3-CT4 grade

Casting no internal shrinkage, external shrinkage defects

Casting black spots after polishing can be controlled with 3%

Casting internal tissue density is good to ensure the heating treatment and machining can be done well

Casting surface roughness good, significantly reduce the working hours of casting burning and polishing

Investment Casting reduce the High Cost of your machined parts, weldments, fabrications and mechanical components by as much as 30 to 50%. From simple to complex shapes, Investment Casting provide you with ideal solution to your low/medium quantity mechanical component requirements.

| Packaging Detail:Carton , wooden case, or requested by customer |

| Delivery Detail:30days |