carbon steel elbow induction heat forming hydraulic machine

| Place of Origin:Hebei China (Mainland) | Brand Name:Fengliyuan | Model Number:YWT-1 | Condition:New |

| After-sales Service Provided:Overseas third-party support available | power mode:hydraulic | size:108mm | color:blue green yellow or white |

This serias of machine can push alloy and carbon steel pipe whith diameter 0.5-58 inch wall thickness from 2-100mm. There are motors drived oil cylinders pushing the pipe ahead at one end .

The following is the part of technic parameter of one of the modle of the elbow machine we made before:

. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

We make designs according to customers' requirements and make products in different specifications as well as various kinds of standard ones. Our main products are hydraulic four-cylinder advanced elbow making machines, pipe machines, tee cold drawn machines and big gantry four-column hydraulic machines.

| Machine name | Processing materials | application |

Elbow machine | Carbon steel | Manufacture the elbows with a diameter between 21mm~1420mm,a wall thickness between 3mm~100mm and a times of more than 1D |

| Alloy steel | ||

Pipe bengding machine | Carbon steel | Bend angle(max):180 degree,bend radius:R=2.5~100 times or more |

| Stainless steel | ||

| Alloy steel | ||

| Pipe expanding machine | Seamless pipes | The diameter range for pipe expansion is 60mm~1200mm |

Tee joint machine | Stainless steel | Forming range:21mm~630mm |

| Carbon steel | ||

| Seamless steel | ||

| Beveling machine | Carbon alloy steel | Processing diameter range 21mm-1620mm |

| Hydraulic press | 1 tons-8000tons |

We have built long lasting cooperating relationships with many companies from home and abroad.

Our main customers abroad

| Country | product model | name of the equipment | |

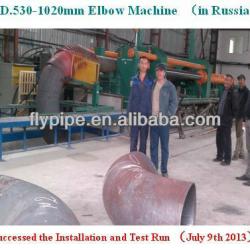

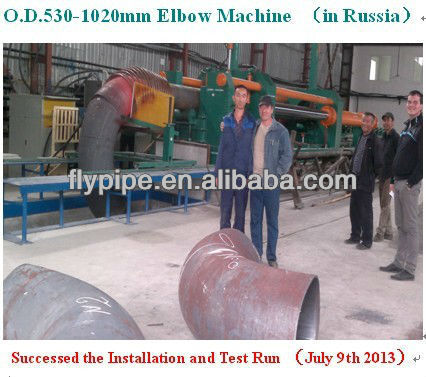

Russia | 1020*14mm | Hydraulic elbow pushing machine | |

| 720 | Elbow mold | ||

| 720mm | Induction heating | ||

And so on | |||

India | 8 inch | pipe expanding machine | |

| 6 inch | Hydraulic elbow making machine | ||

| 133 mm | Beveling machine | ||

And so on | |||

Argentina | 325mmsch80 | Hydraulic pipe expanding machine | |

| 273-325 | Pipe expanding mold | ||

| 159-273 | Pipe expanding mold | ||

Induction heating coils | |||

Singapore | 626 sch40 | Hydraulic elbow machine | |

| 800 T | Hydraulic press | ||

Molds for the elbow machine | |||

Induction heating coils | |||

And so on | |||

Malaysia | 630 sch 40 | Hydraulic elbow forming machine | |

219-630 mm | Dies for the machine | ||

219-630 mm | Induction heating coils | ||

108mm | Hydraulic elbow hot pushing machine | ||

Our company is professional in designing and manufacturing medium frequency heating hydraulic welded pipe bending machine,thick wall elbow forming machine,pipe expanding machine,press,multi functional beveling machine,tee cold forming machine,etcAs soon as we get the basic data of the pipe fittings(the diameter,the wall thickness,the material,etc.)you would like to made with the machine ,our profesional engineers will design the perfect machine unique for you,and then I will send the best quotation to you. Look forward to cooperate with you sincerely. Your earliest reply will be my great appreciation. Welcome to China,welcome to visit our company

Induction heatingis the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, where eddy currents (also called Foucault currents) are generated within the metal and resistance leads to Joule heating of the metal. An induction heater (for any process) consists of an electromagnet, through which a high-frequency alternating current (AC) is passed. Heat may also be generated by magnetic hysteresis losses in materials that have significant relative permeability. The frequency of AC used depends on the object size, material type, coupling (between the work coil and the object to be heated) and the penetration depth

some other products of our company

| Packaging Detail:no package for the main machine, wood case for the small parts |

| Delivery Detail:40 days |