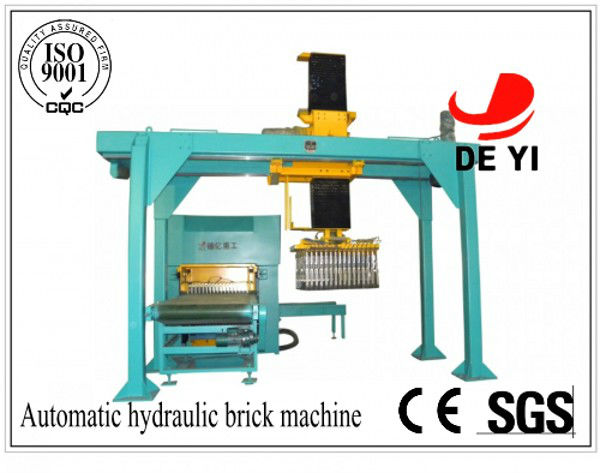

Brick making machine price,automatic brick machine, hydraulic cement brick machine

| Condition:New | Type:Automatic brick making machine | Brick Raw Material:Sand or fly ash with quick lime and cement | Processing:Brick Production Line |

| Method:Hydraulic Pressure | Automatic:Yes | Capacity:5760-7200pcs/hour | Place of Origin:Henan China (Mainland) |

| Brand Name:DEYI | Model Number:DY1100 | Voltage:380V | Power:75kw |

| Dimension(L*W*H):4785*4965*4690mm | Certification:CE/ISO/SGS/National Patent | Warranty:Lifelong Maintenance Service | After-sales Service Provided:Overseas service center available |

| Operation:Simple and convenient | Performance:Stable and reliable | Workshop:Simple bright steel structure | Quality:Higher than JC239-2001 and GB11945-1999 |

| Rate of finished bricks:Above 98% | Preesure:1100T | Keywords:brick making machine price | Productivity:150,000 pcs bricks / day |

Automatic brick making machinery

Contact person: Irene Huang

Mob: 0086 – 150 36111 962

Skype: irene.04011989

Technical parametersof DY1100 multi-functional automatic brick making machinery:

| Nominal Tonnage(KN) | 1100 |

| Pressing quantity(pieces,standard brick) | 32 |

| Pressing cycle(seconds) | 16-18 |

| Pressing direction | Down to up |

| Pressure head journey (mm) | 500 |

| Output(pieces,standard brick) | 5760-7200 |

| Fly ash content(%) | 70 |

| Annual production capacity(pieces,standard brick) | 50,000,000 |

| Annual Fly ash consumption(t) | 80,000-100,000 |

| Total loading power(KW) | 75 |

| Air-exhaust frequency | Over 3 times(self-adjustment) |

| Brick Specification | 240×115×53mm(standard),240×115×90mm(blind-hole); 390×190×190mm(hollow brick)various sizes of colorful paving and square bricks |

| Brick feature | Compact and uniform density |

| Weight(t) | 80 |

| External Size(mm) | 4785X4965X4690 |

Technology featuresof DY1100multi-functional automatic brick making machinery:

1.DY1100 automatic multi-function hydraulic brick machine is our company introduction of absorption of USA and Germany technology research and development a high-tech patent product.

2.DY1100 adopts 3-beam 4-column prestress force tie bar sleeve structure and optimized finite element stress analysis, Enough to withstand two thousand tons of tension.

3.Adopting Germany Siemens PLC program control, human machine interface and touch screen operation.

4.Oil cylinder seals all adopts Germany original parts, cylinder body is forged with double alloy, internal surface by grinding under heat treatment.

5.Adopting built-in displacement sensor in oil cylinder, which can control brick stuffing precisely, high pass rate, low error(error is only 1mm).

6.Hydraulic pressure station is the drive source of hydraulic press. Our company adopts original hydraulic pump and directional valve of Germany, making hydraulic brick machine can realize the multi-stage pressings of pre-pressing, die pressing and maintaining pressing.

Advantages of DY1100multi-functional automatic brick making machinery:

1.It use the double-sides pressure

2.High pass finished product rate

3.PLC control system

4.Full automatic brick machine production line

5.less worker for your brick making plant

6.ISO9001:2000

7.The setting machine will help to put up the bricks

Ourautomatic brick making machinerycan produce several kinds of bricks:standard bricks, hollow bricks, blind hole brick machine,fly ash brick, sand lime brick, autoclaved brick.

Automatic brick setting machine

Russia fair

| Packaging Detail:Standard container, nude packing or in bulk |

| Delivery Detail:60 days after receipt of deposit |