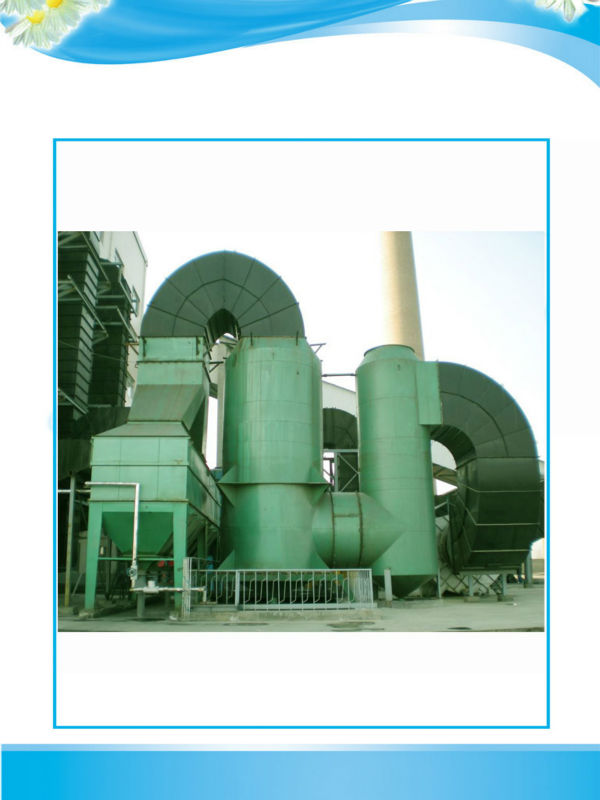

Boiler desulphurization dust removal systems

| Place of Origin:Jiangsu China (Mainland) | Brand Name:JR | Model Number:TS/B | structure:compound |

Description and advantages of the product:

1.anticorrosion, fire resistant

2.high efficiency of desulfurization

3.reasonable price

Unique design,can be run in negative or positive pressure state;

Combination boiler flue gas flue gas desulfurization equipment is used for removal of SO2.

Direct installation of desulfurization equipment for multi-tube cyclone makes the best combination of form.

It is for dust removal and desulfurization of the boilers and furnaces. It has a leading integrated technology and economic indicators at home.

The work theory

It is mainly composed of the cabinet, air inlet and exit, blowing pipe as well as the bracket of water tank.. First put some water in induced-draft fan, the air mixed with smoke and dust enter the equipment, collide and impact the liquid surface, depending on the inertia the soot is caught by the water layer, and then airflow gets through the water layer as the way of tricking, the equipment has the second cleaning, some imperceptibility soot together with the airflow enter the S-shape decontamination chamber. High speed airflow collides the liquid surface, because of centrifugal effect the imperceptibility soot can be caught. At the same time, So the smoke can be absorbed by the desulphurization effectively. The air including water will be dehydrated by the breakwater after cleansing, and expelled to the atmosphere by the fan.

main technical parameters

installation

1. in accordance with the basic map to make up the basis,circular tank and sedimentation tank don't be leakage.

2. when installation ,make sure the tightness of the joints.the gas/ water system donn't be air leakage and water seepage

3. don’t Hit or throw , Welding, cutting, heating any parts of the product.

4. After installation, shall be done the cold gas/water system test run.

5. Depending on the running field condition,can change the desulfurization unit position relative to the dust collector,the basic map also be changed.

Use and maintenance

1. This device can be installed before the draft fan and worked.when running ,make sure the draft fan and the circulating pump opening or closing at the same time.

2. Must be keep the circulating pool level in the normal range for the calibration.should be monitored PH regularly,during the running,the PH not less than 8_10.if below this value ,it is timely to add the new boiler water or deploy the alkaline media

3. adjusted for the amount of fluid rely on the circulating water pressure to adjust the valve A,the chimney gas that non-gray nor "white smoke"shall be well. when determined,don't change the valve.

4. the pre_removal equipment should requir the emissionstandards.should be cleaned the Circulating pool by adjust the valve B to drained the water when the Circulating pool of dust more than exceed 200mm.

5. should regular inspection and cleaning the inlet of the pump to prevent clogging.

6. should be prevent the freezing in winter.

Installation size

Company profile

Our company is a manufacturer and trader specialized in the research, development and production of Dust removal and desulfurization equipment, we have great confidence that we could make it better and better to meet the needs of our client. And we can also promise that our products have the lowest price and best quality.

We are looking forward to cooperating with you.

| Packaging Detail:wooden crate |

| Delivery Detail:15 days after receipt of deposit |