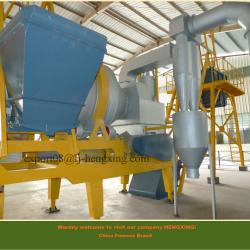

Bitumen Batching Plant, Mobile Asphalt Batching Plant, Bitumen Asphalt Machine (QLB20, QLB30, QLB40)

| Condition:New | Place of Origin:Fujian China (Mainland) | Brand Name:HENGXING | Model Number:QLB20 |

| Voltage:According to clients' local demands | Power(W):98KW | Certification:TUV CE | Warranty:within one year |

| After-sales Service Provided:Engineers available to service machinery overseas | Control system:Mitsubishi PLC, Omron and Schneider Electric components | Products:Mobile Asphalt Batching Plant |

Mobile Asphalt Batching Plant, Asphalt Mixing Plant, Bitumen Mixing Machinery,Automatic Asphalt Mixing Plant, BItumen Asphalt Mixing Equipments

Technical Parameters of Mobile Aspahlt Batching Plant

| Model | QLB20 | QLB30 | QLB40 |

| Productivity | 20t/h | 30t/h | 40t/h |

| Power | 98kw | 132kw | 185kw |

| Batching machine | 5m3*3 | 5m3*3 | 8m3*3 |

| Finished product hopper | 5t | 9t | 9t |

| Output temperature | 120-180°C, adjustable | ||

| Fuel consumption oil | Oil:5-7.5kg/t, Coal: 13-15kg/t | ||

| Options | Coal miller, water dust filter, bag-type dust filter, control room, asphalt heating tanks | ||

Product Introduction(bitumen asphalt mixing plant)

QLB seriesmodular positive asphalt concrete mixing equipments is manufacturered based on foreign countries advanced technology,the machine structure is simple compact with high automation and stabilization. the oil aggregate ration is stable,the finish products quality is high. it realizes efficiency and good economic returns.

1.The burner adopted the auto-fuel technology and the latest pulverized coal jet technology. it realizes the automatic ignition,compete combusition,high thermal sfficiency.

2.The main parts adopt independent combination. control by programmable control program to ensure the centralized control is easy.

3.it is easy to set the drying time so the drying cylinder can reach temprature standards to dry even the wet mineral aggregate and ensure the quality of asphalt concrete requirements.

4.oil aggregate ratio is very accutate by using asphalt spray .

5.using double drum drying ore materila to short drying time units and improve efficiency.

6.It is high full-automatic,save human labor

7. Drying cyclinder structure using heat-resistant and wearable boller steel plate. Using the gear-driven and four cast iron supporting idlers to ensure the work speed reposeful. Intermal blades can mix the material general also reduce the heat lost.

When the aggregate reach desired dry dry index , the drum will discharge the concrete to positive mixer.

8.The finished products is in high quality and stable performance, as the machine used the positive mixing, all kinds of the materials can be mixed together with asphalt better and ensure the high quality, asphalt concrete.

| Packaging Detail:standard sea worthy package, we could packed according to clients' demands |

| Delivery Detail:20-30days after receivng downpayment |