Biomass Sawdust Extruder Machine For Making Briquettes

| Application:Briquette Machine | Production Capacity:800-2000kg/h | Place of Origin:Henan China (Mainland) | Brand Name:De Song |

| Model Number:DS1000/ DS1500/ DS2000 | Voltage:220-380v | Power(W):15-22kw | Condition:New |

| Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

Sawdust Extruder Machine

What can be briquetted?

Almost any biomass can be briquetted. Briquetting plants set so far in India are using saw dust, bamboo dust, bagasse, cotton stalk, coffee husk, groundnut shell, mustard husk/stalk, pine needles, rice husk, sugar mill waste, jute waste, coir pith and other wastes & residues like castor shell, red gram stalk, tobacco stem, tea waste, sander dust, tree bark, wild grasses & shrubs and sander dust etc. can be also be briquetted individually or in combination without using any binder.

How is that going?

Briquetting is a process that biomass is compressed under high pressure and high temperature. The machine uses a large screw to grind, compress and extrude the biomass into briquettes. During this process, no binder needs to be used. So the output briquette is a type of clean and biomass fuel that is ideal for use in furnaces, boilers and open fires.

| Capacity (kg/h) | 140 | 180 |

| Motor power (kw) | 15 | 18.5 |

| Electric heating power (kw) | 4.5 | 4.5 |

| Product size (diameter x length) | 50x45 | 50x45 |

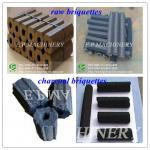

Production Process Of The Charcoal:

1, Use the wood crusher to crush wood into sawdust;

2, Use the sawdust dryer to pull the moisture out of sawdust;

3, Use the sawdust forming machine to press sawdust into stick;

4, Use the wood charcoal bake stove to bake the stick into charcoal;

5, Then use the wood crusher again to break the charcoal into powder;

6, Use the powder molding machine to press the charcoal powder into all kinds of shape(you can custom many kinds of mould);

7, Use the packing machine to package the shaped charcoal.

You can choice it base your raw material,final product and wanted output capacity.

| Packaging Detail:Standard exporting packing or as customer's requirement. |

| Delivery Detail:15 days |