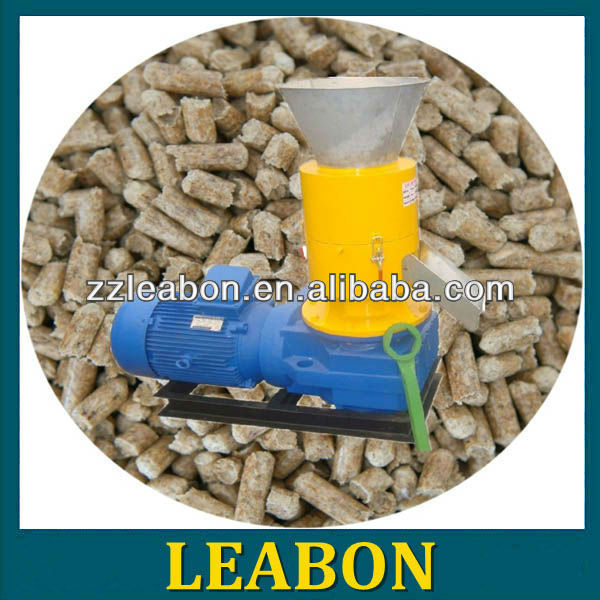

Best selling and top quality Material moisture 13-21% biomass fuel (feed) pellet machine

| Brand Name:LEABON | Model Number:KAF 450 | Place of Origin:Henan China (Mainland) | Power(KW):45 |

| Voltage:380V/50Hz,220V,380V | Dimension(L*W*H):1.8* 1* 1.65(m) | Material moisture:13-21% | Weight:1200KG |

| Condition:New | Payment Terms:L/C,T/T,Western Union |

Biomass fuel (feed) pellet machine

Overview: With the biomass fuel become more popular, we improved the main parts, which is more suitable for making the sawdust pellets better. Now it could processmore kinds of sawdust,paddy straw,sunflower stalk,hulls,forestry wastes,woodchips,chemical wasteandmany other wastesorsolid powder materials.

Machine Introduction:

Biomass fuel (feed) pellet machineis applied to make the agro-forestry wastes into solid fuels or wood pellets. It includes an imperative feeder system, stainless screw conditioner, high quality gearbox, ring die and lubrication system. The material is transferred to the conditioner by a screw feeder, then the conditioner can make different materials fully mixed. The conditioner plays a key role in softening raw materials by utilizing water or steam. After softening, the raw material is sent by a feeder to the pelletizing chamber. By spinning rollers in the chamber force the material through the holes of the die, thus pellets are formed. After pelletizing, the length of the pellet can be cut according to different user's request.

Working principle:

The raw material is under dried condition, which is compressed, and formed into small eraser-sized bits, the final pellets is clean, pleasant and smooth

Biomass fuel (feed) pellet machineTechnology Data spare parts:

| Model | Capacity (kg/h) | Motor | Pellet Size | Solid molding density | Applicable materials moisture content | Machine Dimension | Machine Weight |

| KAF-200 | 100-150 | 7.5kw | 6-10mm | 1.1-1.4 g/m3 | 13-21% | 1* 0.45* 0.8(m) | 320 kg |

| KAF-250 | 150-200 | 11 kw | 6-10mm | 1.1-1.4 g/m3 | 13-21% | 1.2* 0.6* 1.3(m) | 350 kg |

| KAF-300 | 200-300 | 18.5/22 kw | 6-30mm | 1.1-1.4 g/m3 | 13-21% | 1.3* 0.6* 1.3(m) | 450 kg |

| KAF-400 | 400-600 | 30 kw | 6-30mm | 1.1-1.4 g/m3 | 13-21% | 1.6* 1* 1.55(m) | 1600 kg |

| KAF-450 | 500-850 | 37 kw | 6-30mm | 1.1-1.4 g/m3 | 13-21% | 1.8* 1* 1.65(m) | 2000 kg |

| KAF-550 | 1000-1500 | 55 kw | 6-30mm | 1.1-1.4 g/m3 | 13-21% | 2.1* 1.8* 2.15(m) | 2500 kg |

Materials and final products:

Wood chips, rice husk, sunflower seed shells and agricultural wastes.

Machine Features:

1.Atomatic refueling device for roller.This device keeps the machine work continuously and improve the capacity greatly

2. The drive part of the machine including motor optimize the high quality SKF bearings made in Switzerland, which ensure high efficient and steady driving with low noise.

3. The imperative feeder device is adopted, which making the machine operate smoothly as the material like wood sawdust, corn, wheat, and rice straw is very light, so they are needed to be pushed into pelletizing chamber by force.

4. Full Stainless steel strengthening feed conditioner, adopts the frequency-conversion speed regulating control to guarantee quality wood pellet.

5. The alloy steel die is made by international advanced German gun drill and American vacuum furnace, has long service life and ensure smoothly pelletizing and high quality.

6. The international advanced compensation type flexible coupling is of novel and compact structure, safety, low noise and less trouble.

7. Permanent magnet device can remove impurities in the pelletizing process

Atomatic refueling device for roller:

Superiorities:

1. Efficient. Wood pellets are an efficient source of heat because they contain very low levels of moisture and ash, when compared to woodchips or cordwood. Virtually all of the material is burned and converted to heat.

2. Cost-effective. Wood pellets are economically competitive with home fossil fuel options and electric heat.

3. Environmental friendly. Wood pellets are a sustainable fuel source, and burningwood pellets is carbon neutral.

4. Renewable. Wood pellets are a biomass product made of wood waste or other forest-thinning byproducts. According to data collected by the Pellet Fuels Institute, wood pellets are an unlimited fuel source.

5. Broad application. Wood pellets can be used in a lot of appliances such as stoves, furnaces, boilers and other heating systems .

Delivery of machines

CE approved

More information and technology questions, welcome to contact us .We are looking forward to hearing from your enquiry !

| Packaging Detail:Standard packing |

| Delivery Detail:within 20 days after receipt of deposit |