Best seller drum drying machine with professional supplier made in China

Progressive drum drying machine, 1.Time delivery, 2.With adjustable motor, 3.Raw material with boiler plate, 4.OEM service offer - details see: https://www.machineto.com/best-seller-drum-drying-machine-with-professional-supplier-made-in-china-10285270

| Product Type:Drum Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:Guoxin | Model Number:any type as required |

| color:any color is available | quality:export standard | motor power:7.5-90kw | capacity:1.5-36t/h |

| warranty:1 year | condition:new | shipping:by sea | diameter:1-4m |

| installation:under technician's guidance | gradient:3%-5% | Machine Type:Evaporator |

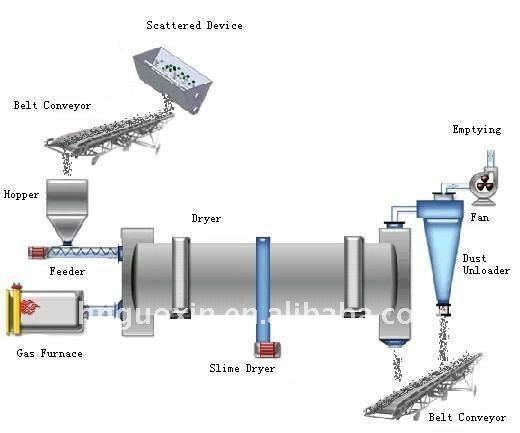

Introduction of drum drying machine:

- The rotary drier(drying machine) is used for drying materials with a certain humidity or granularity It is applied to building materials,metallurgy and chemical industry.It can be used to dry the slag,limestone,coal powder,clay and other related materials.

- The rotary dryermainly consists of rotary body,raw material feeding plate,driving and supporting device.Our drier is of reasonable structure,high efficiency,low energy consumption and convenient for transportation

Working principle of drum drying machine:

- Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer.

- When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls. This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow).

- The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the dryer is called a direct heated dryer. Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated.

- When the gas stream is preheated by some means where burner combustion gases do not enter the dryer, the dryer known as an indirect-heated type. Often, indirect heated dryers are used when product contamination is a concern.

Technical parameters of drum drying machine:

Model | Main reducer | Speed (r/min) | Production capacity (t/h) | Power (k w) | Volume(m3) | Weight(t) | |

| Model | Ratio | ||||||

| Φ0.8X1.0 | JZQ450-16-11 | 7.2 | 0.8-2.2 | 4 | 5.02 | 6.9 | |

| Φ1.2X12 | ZL50-16-1 | 5.8 | 1.8-5.5 | 11 | 13.31 | 13.8 | |

| Φ1.5X12 | JZQ500-111-2F | 16.46 | 4.8 | 4-9 | 15 | 21.2 | 22.3 |

| Φ1.5X 15 | ZQ50-1611-2 | 16.46 | 4.8 | 4-10 | 18.5 | 26.5 | 28.8 |

| Φ1.8X14 | JZQ650-111 | 18.84 | 3.2 | 6-12 | 30 | 48.22 | 39.8 |

| Φ2.2X14 | JZQ750-111 | 31.5 | 3 | 10-22 | 37 | 53.2 | 48.3 |

| Φ2.2X16 | ZJQ750-111 | 31.5 | 3 | 10-23 | 37 | 60.1 | 51 |

| Φ2.2X18 | JZQ750-111 | 31.5 | 3 | 10-25 | 37 | 70.43 | 53.3 |

| Φ2.4X18 | ZL85-13-1 | 27.16 | 2.83 | 20-40 | 45 | 81.4 | 68.8 |

| Φ2.4X20 | ZL85-13-1 | 27.16 | 2.83 | 20-40 | 45 | 90.43 | 78.4 |

| Φ2.8X24 | ZL100-16-1 | 31.5 | 2.59 | 20-45 | 55 | 147.8 | 97 |

| Φ3.0X25 | ZL100-16-1 | 41.54 | 2.6 | 25-48 | 75 | 176.7 | 110 |

| Packaging Detail:Standard packing, Seaworthy packing,non-packaging,as required |

| Delivery Detail:Within 345 working days after receive advanced payment |