Best Price Given aac block plant

| Place of Origin:Henan China (Mainland) | Brand Name:King State | Model Number:50000CBM,100000CBM | After-sales Service Provided:Overseas service center available |

| Certification:ISO9001:2008; CE | Quality:reliable | Color:as you require | Service:timely, professional |

| Application:AAC block | Installation:under our engineer guide | Guarrantee:1year | Spare parts:supply in whole year |

| Main machine:cutting machine | Maintenace:easy and low cost |

high quality aac block

Autoclave Aerated Block AAC block

We are most professional manufacturer of autoclaved aerated concrete (AAC) plants for more than 12 years, and we can supply complete set of autoclaved aerated concrete plant with 50 000m3, 100 000m3, 150 000m3, 200 000m3, 250 000m3, 300 000m3 capacity annually, including plant design, equipments installation, technical instruction, personal training, etc, and also can design and manufacture as per clients' requirement.

Raw materials:Fly ash or sand,cement, lime, sand, gypsum, aluminium powder, water

The equipment will be divided into two parts: specialized equipment and universal equipment.autoclaved aerated concrete AAC block Specialized equipment includes:

1. Cutting equipment: tilting crane, cutter.

2. Proportioning equipment: elecronic measuring scle, slurry beating machine, slurry storage tank, slurry mixer.

3. Pouring and autoclave equipments: aluminum powder mixer, pouring mixer, mould, side plate, autoclave truck, carrier car.

4. Enviornment protect equipments: dust remover.

autoclaved aerated concrete AAC block Other relative equipments as follows:

1. Cutting machine.

2. Tilting hanger, mould, side plate, hardening cart, mould frame, mould bottom, casting machine, hoist

3. autoclave, horizontal installation stem boiler

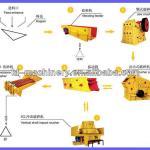

The whole line is mainly divided into five working periods:

1. Raw material preparation and storage

2. Ingredients, mixing, pouring

3. Static stop maintenance

4. Cutting section

5. Grouping and autoclave

AAC block

autoclaved aerated concrete Our service and advantages:

1.Full service: installation ,training,commissioning,competitive &good quality

2.One year guarantee

3.one year easily damaged spare parts for free

4. vibration system: this system adopts multi-sources vibration syste,, which make sure the vibration frequency on every points in the table are the same.

5.the system can diagnose the production line automatically.

6. every production process can be showed on the screen

7.the advanced technology to make the mould : by heating treatment and adding carbon into steelevery

Raw materials:

Sand, flyash, lime, gypsum, aluminum, cement

Sand formulation

| Paremeter Name | Parameter Value |

| sand | 62% |

| lime | 18-22% |

| cement | 10-12% |

| gypsum | 3% |

| Aluminum powder | 0.0007-0.0008% |

Flyash formulation (alternatively)

| Paremeter Name | Parameter Value |

| flyash | 68% |

| lime | 18% |

| cement | 6-8% |

| gypsum | 2-3% |

| Aluminum powder | 0.0007-0.0008% |

AAC 1/m³ material composition

| No | Name | 1/m³consumption |

| 1 | Sand/Fly ash | 0.42 ton |

| 2 | quick lime | 0.11 t |

| 3. | Cement | 0.048 t |

| 4 | phosphogypsum | 0.018 t |

| 5 | foam stabilizer | 0.18 kg |

| 6 | Aluminum powder | 0.4 kg |

| 7 | used oil | 0.329 kg |

| 8 | Eletricity | 12 kw |

| 9 | Coal | 0.014 t |

\

| Packaging Detail:standard container, spare parts is packed in wooden cases |

| Delivery Detail:30days after the order confirmation |