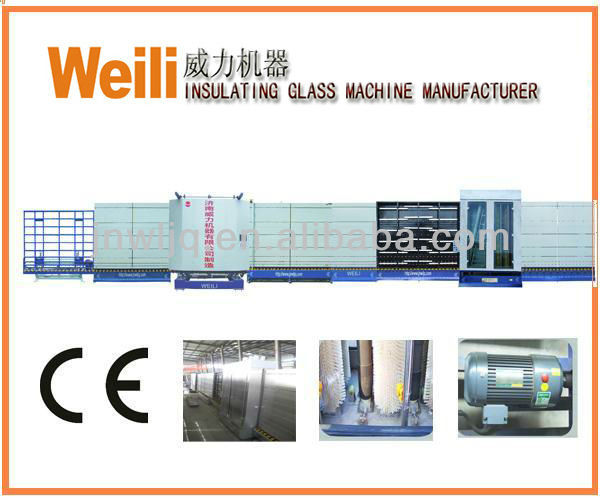

automatic vertical insulating glass production line

| Condition:New | Machine Type:Insulating Glass Production Line | Production Capacity:20set/month | Place of Origin:Shandong China (Mainland) |

| Brand Name:WEILI | Model Number:LBZ2500PC | Voltage:380V 50HZ | Power(W):38KW |

| Dimension(L*W*H):24300*2600*34500 | Weight:7500KG | Certification:CE | Warranty:one year |

| After-sales Service Provided:Engineers available to service machinery overseas | Control System:PLC |

Insulating Glass Production Line---LBZ2500PC Vertical Insulating Glass Production Line

Main model

| Model | Min.Glass Size (mm) | Max.Glass Size (mm) | Low-E Glass | Stepped Glass | Triple Glass | Dimension (mm L*W*H) | Sections |

| LBZ2500PC-08 | 450*450 | 2500*3000 | Optional | Optional | yes | 24300*2600*3450 | 8 |

| LBZ2500PC-07 | 450*450 | 2500*3000 | Optional | Optional | yes | 21300*2600*3450 | 7 |

| LBZ2500PC-06 | 450*450 | 2500*3000 | Optional | Optional | yes | 18300*2600*3450 | 6 |

Main component:

| No. | Name | From | |

| 1 | PLC | MITSUBISHI | Japan |

| 2 | Touch screen | Hsintek | Taiwan |

| 3 | Optoelectronic switch | CONTRINEX | Switzenland |

| 4 | Transducer | DELTA | Taiwan |

| 5 | Vacuum generator & Sucker | Chelic | Taiwan |

| 6 | Low-voltage component | Schneider | France |

| 7 | Solinoid valve | Airtac | Taiwan |

| 8 | Coating detection system | Omron | Japan |

| 9 | Bearing in washing section | SKF | Sweden |

| 10 | Linear guide rail | Samick | Korea |

| 11 | Servo motor | DECO | Taiwan |

| 12 | Delivery motor | OTGBrand | Shanghai |

| 13 | Gas-type fitting & Triplet | Airtac | Taiwan |

| 14 | Proximity switch | AUTONICIS | korea |

Features and functions:

1. The machine have Loading section, washing and drying section, transportation section, Washing quality inspection & Aluminum spacer mounting section, transportation section, Servo driving plate press section, tilt unloading section.(8 sections)

2. The machine adopt the advanced servo motor, gear and rack press technology, through digital PLC control system, main components are world famous brand. The whole machine features powerful function and reliable.

3. The production line can produce triple glazing, double glazing, curtain wall glass, over long glass unit and stepped glass

4. Automatic LOW-E coating glass identifying

5. The machine has automatic and the manual two operating modes. They are more convenient and succinct;

6. Cleaning dryer and the water tank was made by stainless steel processing manufacture, transmits the roller for to bear the acid and alkali rubber roller, according to the glass thickness transmission roller spacing may the automatic control.

7. The press panel board of panel pressure board adopts to imported material, the press system and panel press system are controlled by the Servo motor , gear and rack press technology system, which guarantee the two pieces glass press together safely and steadily and the processing accuracy.

8. This machine includes One lift, when you assemble a very big spacer bar on the glass, it's easier to use this lift to put it on to glass.

Technical parameter:

| Power supply: | 380V 50Hz |

| Air consumption: | 800L/min |

| Power: | 34kW |

| Max. process dimension: | 2500*3000mm, 2500*3500mm(over long unit) |

| Min. process dimension: | 450*450mm |

| Max thickness of the insulating glass: | 40mm |

| Max. process speed: | 45m/min |

| Washing glass thickness: | 2-12mm |

| Dimension: | 24300*2000*3450mm |

| Total weight: | 7500kg |

| Packaging Detail:plywood pallet |

| Delivery Detail:30 working days after receiving deposit |