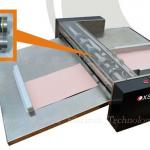

Automatic Trimming Transverse Cutting Machine

| Type:Paper Cutting Machine | Place of Origin:China (Mainland) | Brand Name:Guangcheng | Model Number:GC-1200/1400 |

GC-1200/1400 Automatic Trimming Transverse Cutting Machine

1.Unwinding Part:

a. Using 3 inches or 6 inches air expended shaft.

b. Unwinding tension is 10Kg, magnetic power brake.

c. Manual feeding mechanism.

d. Electric feeding mechanism.(optional)

e. Unwinding adopts Taiwan Chengbang 1.5Kw frequency control of motor speed.

2.Correction Part:

a. Adopts the negative pressure adsorption tracking correction platform.

b. Using linear guide to correct by sliding.

c. Adopts Taiwan Futai photoelectric tracking and locating system.(ordinary optional)

e. Unwinding Japan Sanqiao correction.(optional)

3.Trimming Part:

a. Using Taiwan frequency conversion motor to drive the circular blade.

b. Precision grinding of the circular blade axis and bedplate of cutter to guarantee cutting accuracy.

4.Transverse Cutting Part:

a. Main engine uses Taiwan Chengbang 2.2Kw electric brake motor.

b. Cutter pulling part adopts Japan Yasukawa servo motors of 3.0Kw high power.

c. Negative pressure adsorption tracking platform to ensure material smoothly.

d. One set of color code tracking device, Taiwan Futai photoelectric.

e. Using complete sets of blade (domestic brand Jialong blade).

f. Adopts guide pillar cutter positioning, Japan Takano brand.

g. 90 degrees adjustable blade bedplate and cutting position.

h. The pulling roller is made of polyurethane material.

5.Control Part:

a. Operation interface adopts 5.7 " color touch screen.

b. All control part adopts Taian frequency inverter.

c. Company own production of PLC.

d. Each pulling roller and the floating roller adopt cylinder pressure damping methods.

6.Trimming Part:

a. Vertical and horizontal shaking and swing arm flapping paper, automatic trimming device.

b. Using infrared photoelectric to control the stack height.

c. Four assembling structure ladders

7.Machine Parameters:

a. Cutting width: 1200mm

b. Unwinding diameter: 1500mm

c. Cutting speed: 140 times / min (MAX)

d. Transverse Cutting accuracy: ± 0.15mm

e. Longitudinal Cutting accuracy: ± 0.10mm

f. Working voltage: 380V

g. Total power: 8Kw

Characteristics

1.Segmental type designed, can be freely collocated according to customers’ requirement.

2.Cutter poisoning adopts the guide pillar and bushes structure of precision die cutting machine, always keeps up and down linear motion during operation, ensures fully usage machine’s functions and greatly improves the stability.

3.Floating roller unique vertical swing arm designed, adopts cylinder damping at the same time, capable for materials with any thickness and weight.

4.Suitable for whether plain materials or printed composite material from 40g to 400g.

5.High speed and high accuracy, compared with the domestic industry, it is more advanced.

6.Reliable design and high quality related components, excellent stability.

7.The company is a mechanical and electrical integration enterprise, convenient maintenance.

| Packaging Detail:by wooden box |

| Delivery Detail:40days |