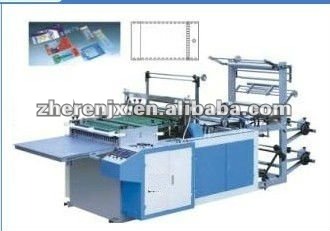

Automatic Heat Sealing And Heat Cutting Bag Making Machine

| Condition:New | Application:Beverage | Packaging Type:Plastic film | Packaging Material:Plastic |

| Automatic Grade:Semi-Automatic | Driven Type:Electric | Power:4.7KW | Place of Origin:Zhejiang China (Mainland) |

| Brand Name:ZHEREN | Model Number:RDL-A | Material:OPP.BOPP | Type:Packing Machine,Sealing Machine |

Function:

| Application | Our this equipment is applicable for making BOPP.OPP.and PE heat-cutting bags with or without printing ,which is a kind of ideal equipment for making sock bag ,towel bag,bread bag and ornaments bag.etc |

| Profile | 1, local touch-screen computer configured to operate |

| 2, arbitrarily set a long-step electric track, a smooth, lost support from the standard parking | |

| 3, feed off automatic shutdown, auto-punch | |

| 4, while at the end of the roll-ultrasonic welding, in particular, solid, smooth | |

| 5, automatic temperature and automatically correcting leaks | |

| 6, while cutting edge automatic closure, automatic nesting |

Main Specification:

Common matters | Raw material | BOPP ,OPP .PE | ||||

| Model Type | RDL-700A | RDL-800A | RDL-900A | RDL-1000A | ||

| Max.Width of Film Roll | 700mm | 800mm | 900mm | 1000mm | ||

| Max.Cutting Length | 50-700mm | 50-700mm | 50-700mm | 50-700mm | ||

| Max.Bag-making Width | 680mm | 780mm | 880mm | 980mm | ||

| Production Capacity | 40-140pcs/min | 40-140pcs/min | 40-140pcs/min | 40-140pcs/min | ||

| Total power | 3.6kw | 3.8kw | 4.5kw | 4.7kw | ||

| Weight of Machine | 900kg | 1000kg | 1100kg | 1200kg | ||

| Overall dimensions(L*W*H) | 3500*1100*1800mm | 3500*1200*1800mm | 3500*1300*1800mm | 3500*1400*1800mm | ||

Control Part | 1 .The whole machine equipped with the microucomputer control | |||||

2.Step motor corol the material –pulling | ||||||

3.The main motor 1.5kw equipped with the invertor which is adjustable speed motor | ||||||

Unwinding part | Equipped with two unwinding frame | |||||

Two unwinding shaf equipped with two sets cone taped shaft | ||||||

| Feeding part | One 400W DC motor pull a set of rubber roller .conveying the material to the waiting area | |||||

With double sides adhesive tape | ||||||

One photoelectric switch control the DC motor,Conveying the length of material | ||||||

| Motor Part | With step motor driving the main motor | |||||

Winch rocker push lighty connecting bar structure.push the cutting knift | ||||||

with the cone taper shaft | ||||||

Optional device:

| Motor | Step motor or Servo motor |

| Control | microucomputer control or PLC control |

| Recommend supporting equipment | Edge folding and Winding machine |

| Packaging Detail:As customers's requirement ,plastic film or wooden case |

| Delivery Detail:20Days after received the balance |