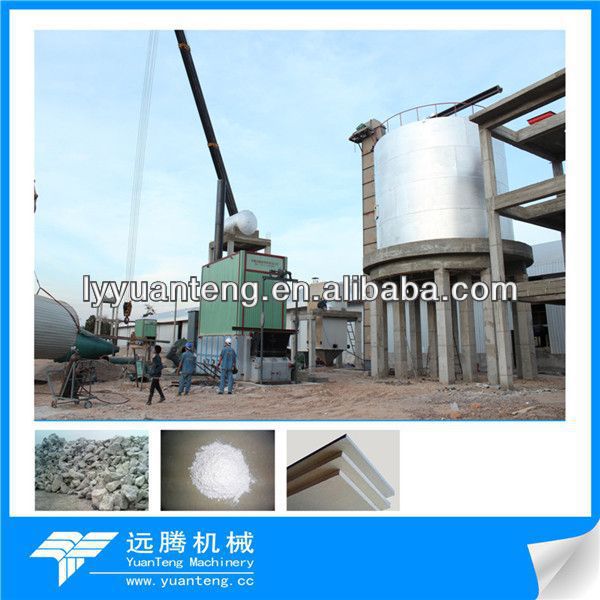

automatic gypsum powder for drywall production line with high quality and high profitable production line

| Condition:New | Application:Construction area | Automatic Grade:Automatic | Place of Origin:Shandong China (Mainland) |

| Brand Name:YT | Model Number:YT2010 | Voltage:client industrial voltage | Certification:CE ISO9001 |

| Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas | Working time:contious | Fuel consumption:Lower |

| Drying type:Boiling furnace | Raw material:Gypsum rock or phosphogypsum waste |

automatic gypsum powder for drywall production line

adopts boiling furnace, high-voltage electrostatic dust removing and other advanced equipment, it is energy-saving and environmental protection.

| Construction gypsum powder production line description |

| Capacity: 30,000 ton/year~300,000 ton/year Automation: fully automatic Calcination system: using boiling furnace to calcine, adopting heat conductive oil furnace as heat source Fuel: coal, natural gas, heavy oil, diesel oil Main materials: natural gypsum rock, desulfurization gypsum, dephosphorizaiton gypsum Standard of product quality: In conformity with national standard “GB/T 9776-2008 construction gypsum” |

Natural gypsum generally includes dehydrate gypsum and anhydrous gypsum. In order to get the valuable materials, generally,

we get semi-hydrated gypsum through heating the dehydrate gypsum.

Gypsum Powder Production line Main Technologygypsum mine ->first breaking ->second breaking ->grinding ->calcining ->aging ->finished products (CaSO4.1/2H2O)

Gypsum Powder Production line Raw MaterialsContent of CaSO4.2H2O in gypsum mine 80%

The grade of mine and the crystal configuration will influence the quality of semi-hydrated gypsum

| Packaging Detail:containers.ship or railway.it will need about 4-20containers,which depends on production capacity |

| Delivery Detail:90days |