Automatic Dry Mixing Plant

| Condition:New | Application:The Production of Mortar | Place of Origin:Henan China (Mainland) | Brand Name:VICTORY |

| Model Number:AUTOMATION | Voltage:380V | Weight:150T | Features:Full Automatic Control |

| Certification:ISO9001 | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | Name:Full Automatic Dry Mortar Production Line |

| Color:According to requirement of cutomers |

Automatic Dry Mixing Plant

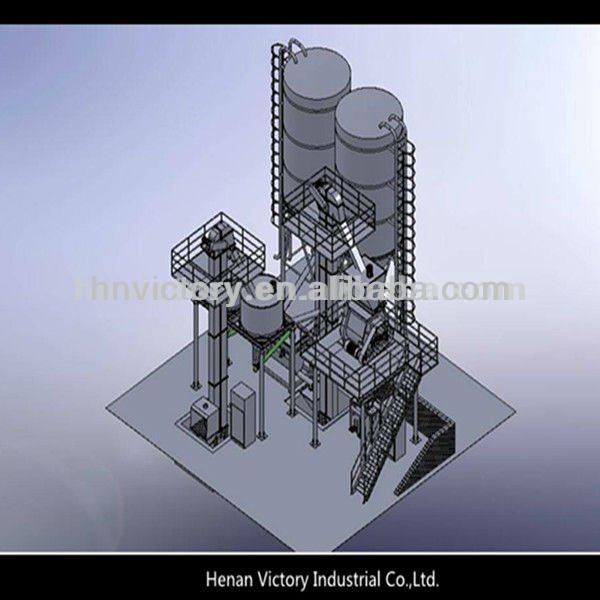

Automatic dry mixing plant is based on the latest design concept in Europe, this production adopts the advanced computer PLC auto-control system, whose production capacity can reach 30-100 thousand tons per year depend on the system configuration. The production line consists of material storage system, conveyor system,filter system,automatic batching system, mixer system, control system,air compressor system , packaging system,ect.

The approximate work process of the device is as follows:

according to requirements of the customers, the system can be equipped with 3-6 bulk storage bins, the material which will, after being processed by the batching system, be conveyed to pending-for-mixing bin, and then fed into the high-efficiency biaxial agravic mixer for continuous mixing. The finished product in conformity with mixing accuracy requirements can be sent to the finished product warehouse shortly to wait for the automatic package.After packing, it can automatically transport to the warehouse.

Featured with the automatic operation andfilter system, the device not only can decrease labor intensity but also effectively reduce dust pollution.

The flow diagram :

A brife view:

The device can also manufacture the following mortars:

1) Masonry mortar

2) Thin and smooth wall mortar

3) Hand-plastering screeding mortar

4) Colored coating mortar

5) Water-proof mortar

6) Plaster powder

7) Wall plastering mortar

8) Ceramic tile adhesive mortar

9) Self-leveling mortar

10) Heat-preservation mortar

The Main Parameters Of The Different Produciton Lines:

| Production line mode | Output | Occupied area | Equipment height | Remark of batching and packing |

| Simple | 1-15t/h | 40m2 | 5-10m | Manual batching and packing |

| Basic | 5-15t/h | 40-60m2 | 6-10m | Manual batching, automatic packing |

| Semiautomatic of serial mode | 5-15t/h | 40-80m2 | 8-12m | Automatic batching of coarse material, manual batching of additive, automatic packing |

| Semiautomatic of tower mode | 5-50t/h | 40-100m2 | 10-25m | the same to serial semiautomatic mode |

| Fully automatic of tower mode | 5-50t/h | 60-500m2 | 10-25m | Automatic batching of all raw material and packing |

Our company strictly execute ISO9001 standars of international quality management system and implement the scientific conception of “constant development”.We can offer various kinds of the production lines according to different requirements of customers. Please contact us if you have any enquiry about our products ! Just wating for you !

| Packaging Detail:Wooden box pakage,whose size is designed according to the specifications, which is suitable to transport in the sea. |

| Delivery Detail:Within 25-30 days after we recieved advanced payment |