Automatic capsule filling machine

Automatic capsule filling machine - details see: https://www.machineto.com/automatic-capsule-filling-machine-10303650

| Condition:New | Capacity:99.99% | Control Mode:Full Automatic | Place of Origin:China (Mainland) |

| Certification:CE | Warranty:1year | After-sales Service Provided:Engineers available to service machinery overseas |

Automatic capsule filling machine

Introduction: It adopts multi-bore dosing, intermittent motion and frequency control. It is suitable for automatically completing capsule feeding, separating, filling, (waste capsule rejecting), closing, finished product ejecting for powder or micro medicine in capsule. Its characteristics are advanced structure, the newest closed ten position rotating table , high precision, low noise and best suitable for domestic machine-made capsule, and soon the key parts of the bearing and electrical equipment adopts international famous brand, performance stability and can be run at a high speed. All parts contacting the medicine powder are made of quality stainless stell, provide dust collector device and made according to GMP standard. | |||||||||||||||||||||||||||||||||||||||||||||||||

Main technical parameter

| |||||||||||||||||||||||||||||||||||||||||||||||||

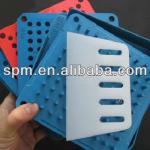

Characters: 1. Small volume, low consumption o fenergy, simplification in changing modules. Easy operating and cleaning. 2. Adopt fugexan eliminating Ma’s trough roller to transmit, less vibration, its noise is lower than 75dB while running at top speed. Dose difference is controlled within ±3%. 3. The rate of capsule filling is 99.99%. 4. It adopts closed environment turret, and sloves the troublesome of installing the mould after cleaning frequently, which rooted in the operation timeof normal models, was lasted for long time so that the medicine powder was stick to oil. 5. The turning-around parts are in full closure, having excellent lubircating conditins. Without old spot on the workiing bench, avoiding the cross pollutioin with medicines, Around the dose dish are fixed with shelter, which can reduse the medicine powder cast from under the dish through another pipe. 6. Meanwhile, it can reduce the dust on the surface of the bench. 7. The working station cam suns under the good lubricating condition, and equipped with the pressure pulverization oil pump, maintains the inner lubrication of cam slot to a full extent, and decreasing the abrasion, thus extends the operating life of change parts. 8. Adopt the SIEMENS man- machine interface( including PLC programming controller, crystal screen displaying the output each minute, accummulative output, dynamic empty capsules and medicine powder state, alaarming for lacking of capsules and insufficient medicine powder stop, trouble shooting display and so on) .It has communication thermal. |

| Packaging Detail:Wooden package |

| Delivery Detail:35days |