Automatic AAC Block Machine, Autoclave Aerated Concrete Block Machine, AAC Plant

| Condition:New | Type:Hollow Block Making Machine | Brick Raw Material:Fly Ash | Processing:Brick Production Line |

| Method:Autoclaved Aerated Concrete | Automatic:Yes | Capacity:40000--300000m3 | Place of Origin:Henan China (Mainland) |

| Brand Name:HUAYI | Certification:ISO9001:2000 | Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas |

| color:as you need | size:as you need | parts:long-term supply at favourable | factory visit:welcome to visit |

| pre-sale service:feasibility study,plant design | advantage:make solid wastes | installation:under our engineer's guide | cutting machine:airborne or ground turning |

Why you choice HUAYI AAC Block Machine ?

1. Applied Germany Ytong & Hess Group technology and combined with China innovation;

2. Cutting machine adopt frame shaking and cutting, which is most reliable designing;

3. Turning table realizing six-sides peeling successfully for aac block cake;

4. Fully automatic & Semi automatic designing;

5. Siemens Brand Motor & PLC Control;

6. Japan YUKEN hydraulic system, Germany Schneider switch;

7. China AAC Association Group best quality and scientific designing;

8. Equipments lifetime maintaining service.

HUAYI AAC Block Machine Reference:

Introduction of AAC Block Machine:

Autoclaved Aerated Concrete (AAC) Block, also called Light Block, used siliceous (fly ash, sand, slag) and calcareous (lime & cement) as the main raw materials, which through the process of batching, pouring, precuring, cutting,

autoclaving, separating and packing to make into the final products. It is new type & environmental construction material and widely used for industry and civil building construction. AAC Block is the most mature technology of

production and application in the worldwide nowadays.

Advantages & Features of AAC Block Machine:

1. Light Weight: 300~800kg/m3

2. High Intensity: 3.5~10.0Mpa

3. Good Thermal Insulation Property: 0.1~0.20W/(m · k)

4. Keeping Temperature, Heat Resistant, Fireproof

5. Good Sound Insulation

6. Earthquake Proof

7. Good Machinability

8. Conveniently Mechanized Construction

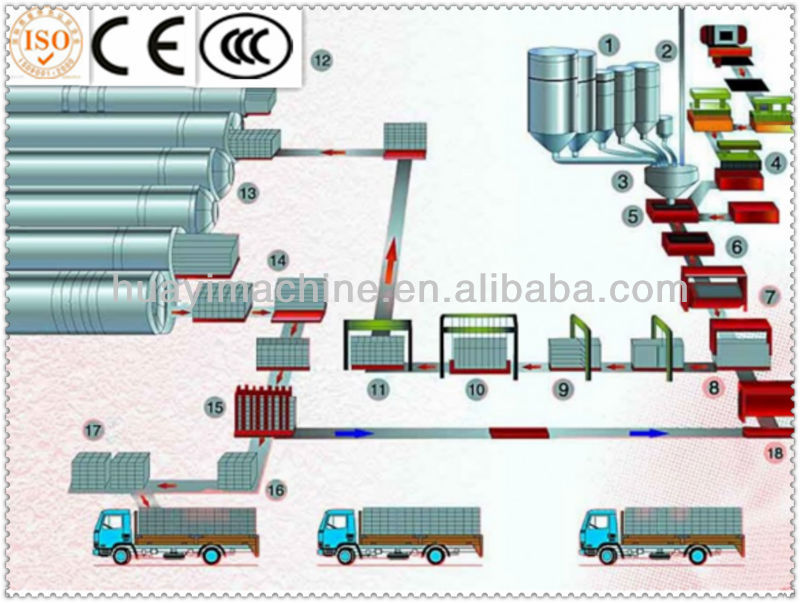

Production Engineering of AAC Block Machine:

1. First, dose and match measured raw materials

2. After distributing, feed raw material into pouring mixer to make slurry

3. Through thoroughly mixing, the slurry is poured to mould

4. After precuring with a certain temperature & time, the block would reach certain hardness prepare for cutting

5. Tilting hoister would turn over 90 degree of mould

6. Then open the mould & separate it from block, take the block with side plate with cutting cart

7. The block then be cut through the cutter firstly of two vertical sides of block

8. Secondly the horizontal cutting

9. Finally the vertical cutting

10. After cutting, the block is hanged to trolley with side plate by semi-finished product hoister

11. Organizing the cut blocks and put them into autoclave

12. Hardening the blocks under certain temperature and pressure

13. Take finished products out of autoclave

14. The finished product hoister takes the finished product to stock shield

15. Packed for loading

16. The side plate return back by side plate roller

17. Side plate would be organized with open mould

18. Clean the mould and preparing for next pouring

19. Steel bars processing line for slab production

Pre-sales:

1. Based on customer's requirement, we select equipment type in the principle of "Best cost performance is reached with most economical investment".

2. Provide the most reasonable program and give necessary illustration till accordant with customer.

3. Through negotiation, technical engineer can be sent to scene for layout for customer.

Mid-sales:

1. Design the technical documents such as whole equipment layout, construction bases layout, equipment installation drawings based on the scene.

2. Produce the equipments strictly as the contract when the customer is doing base construction.

3. Inspection before delivery, shipment organization and customer take-over.

After-sales:

1. Technical engineer will be sent to scene for instruction, installation and test run.

2. On-spot training for customer operator after installation and debug.

3. Irregular return visit to customer after normal production begins

| Packaging Detail:container |

| Delivery Detail:25-40days |