Automatic AAC Block Machine, Autoclave Aerated Concrete Block Machine, AAC Plant

| Condition:New | Type:Paving Block Making Machine | Brick Raw Material:Fly Ash | Processing:Brick Production Line |

| Method:Autoclaved Aerated Concrete | Automatic:Yes | Capacity:50,000m3/year, 100,000m3/year, etc | Place of Origin:Fujian China (Mainland) |

| Brand Name:HENGXING | Model Number:AAC | Voltage:As per clients' demands | Certification:CE, CCC, ISO9001, ISO14000 |

| Warranty:One year after installation | After-sales Service Provided:Engineers available to service machinery overseas | Control system:Mitsubishi PLC, Omron and Schneider electric components | Mixer:Horizontal twin shaft mixer |

| Delivery time:20-30days after receiving downpayment | Package:Standard seaworthy package | Payment terms:30% as downpayment, balance received before delivery | Service:Installation and training |

AAC Plant, Automatic AAC Block Machine, Automatic Aerated Concrete Block Plant

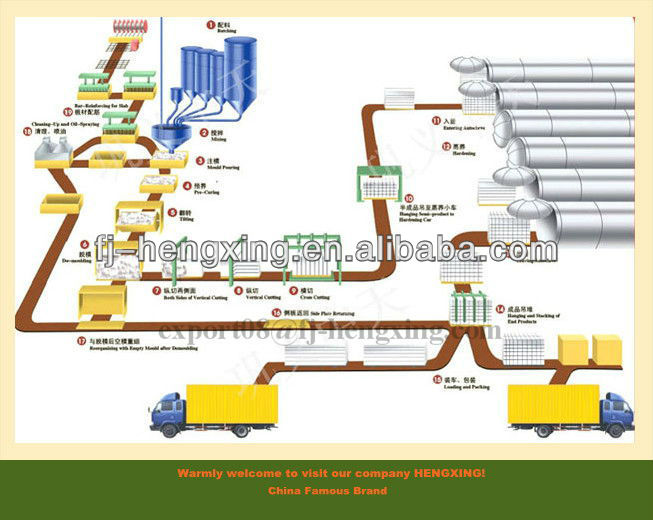

AAC Block forming process

1 The Preparing of The Raw Materials

A. The Preparing of The Slurry

B. The Preparing of The Lime

C. Cement

D. Stone Powder

E. Waste material

2. Batching, Mixing, Pouring

3. Resting and Pre-curing

4. Demoulding, Cutting, Grouping

5. Curing, Finished Product Leaving Autoclave

6. The Reclaim System of Waste Water & Slurry

Planning and Design:

Factory covers an area of 25 acres or so.

There should be raw material area, finished block area and production area. Production process includes raw material disposal, rated material pouring, curing, cutting and steaming procedure.

From building foundation to equipments installing and testing, to trial producing, it will take 4-5 months.

Plant design: 2000 m2 or so.

Material:

1. Flyash: get dry ash from power plant

2. Cement: cement in bulk

3. Lime, gypsum and aluminum powder (buy in local area)

Water, electricity and steam supply:

1. Water supply: build a well or use waste water

2. Electricity supply: install a 315kv transformer

Product quality and specification

Quality

We produce according to PRC standard GB11968-1997 “Aerated Autoclaved Concrete Block Technology”.

Welcome to visit our company for more reference!

| Packaging Detail:Standard seaworthy package |

| Delivery Detail:50-60 days |