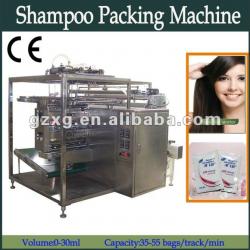

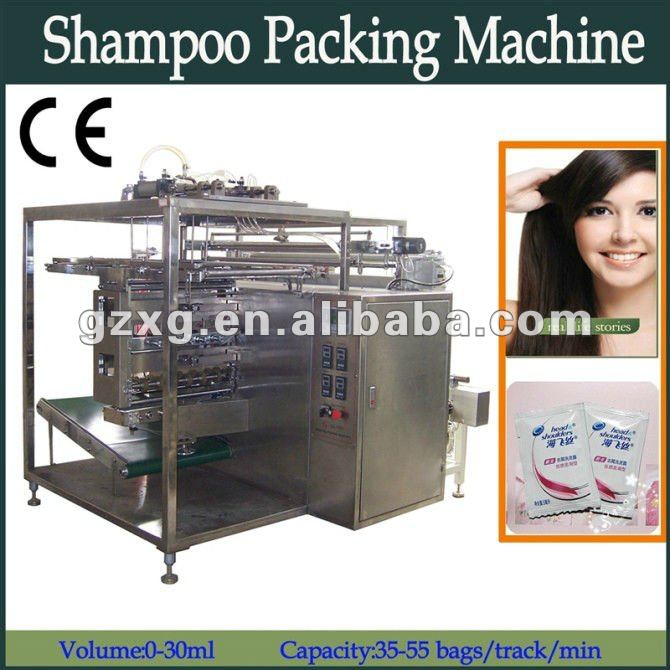

automatic 4 lanes 4 side sealing shampoo packing machine

| Type:Sealing Machine | Condition:New | Application:Commodity | Packaging Type:Film,bags or sachets |

| Packaging Material:laminated or composite film that can be heat sealed | Automatic Grade:Automatic | Driven Type:pneumatic + electric | Voltage:220V.50hz,380V/50HZ |

| Power:2.7 KW | Place of Origin:Guangdong China (Mainland) | Brand Name:Xuguang | Model Number:DXD-Y4 |

| Weight:350 KG,320 kg | Certification:CE certificate | After-sales Service Provided:Engineers available to service machinery overseas | control system:PLC control system |

| machine's diamention:L:1100 W:1000 H:1700 mm | packing speed:160 bags/min | measuring mode:measuring pump | measuring range:1-30ml |

| air source:0.24cbm/min,0.6Mpa | bag making size:L:30-140 W:25-60 mm | control mode:PLC control system |

Products Description

Automatic 4 lanes 4 Sides Sealing Liquid Packing Machine

Applicable Scope

1. Be suitable for all kinds of industries like food; medicine; cosmetic;industrial products

2. The products packed is shampoo, soap liquid, milk, soybean oil, water, tomato sauce,fruit juice, mineral ,fruit sauce, butter etc.

Technical Parameter

| Model | DXD-Y4 |

| Machine speed | 160 bags/min |

| Bag size | (Length)30-140 mm (Width) 25-60 mm |

| Film Material | Laminated or Composite film that can be heat sealed / non-woven fabric/paper-plastic film |

| Bag type | 4-edge sealing |

| Notch | Flat notch/pattern bag-linking/zipper/straight bag-linking |

| Voltage | AC380V/50HZ |

| Total Power | 2.7 KW |

| Measuring range | 1-30ml |

| G.W | 320KG |

| Control System | Taiwan Delta PLC control system |

| Measuring Mode | Fluid pump |

| Machine material | Stainless Steel 304(SS304) |

| Machine Dimension | 1100*1000*1700mm |

| Air source | 0.24cbm/min.,0.6Mpa |

| Brand | Xuguang |

Features:

1) Multi-lanes packing machine adopt advanced PLC and photoelectric control system.

2) Be able to weight, bag-making, filling, sealing, cutting, lot number, cutting easy tearing notch etc. Automatically, it can be operated by one person only.

3) To has color control system which can get the complete trade mark design (Photoelectricity control system).

4) The machine fix stepper motor controller, its advantage is precise, needless to adjust other parts

5)Intelligent temperature control by temperature controller to make heat balance better. use bilingual(Chinese and English) display screen control system and stainless steel (SS304) cabinet

6) Fine packaging performance, low noise, clear sealing texture and strong sealing performance

7) With electrical printer device (be able to code the date and a lot number on the sachet)

8) Don’t need to change new mode if you adjust the length of bag, only need to set the length you need on screen of the machine)

9) Advantage: to operate simply; high accuracy; save electricity and fast speed.

10) Disadvantage: if one of filling pump is broken and others also can not work continuously.

11) Automatic pipe can bring the liquid to pack from big store liquid automatically.

12) For the quantity, it can be adjusted by operator's requests freely.

13) Operation manual and warranty card will be delivered to the clients with machine

Below Are Some Sample Pictures

| Packaging Detail:wooden case with metal frame |

| Delivery Detail:about 30 working days after receipt of deposit |