Artificial Quartz Stone Production Line

| Place of Origin:Henan China (Mainland) | Brand Name:DAJIA | After-sales Service Provided:Engineers available to service machinery overseas | Color:As requested |

ArtificialQuartz Stone Production Line

Introduction of Artificial Quartz Stone Production Line:

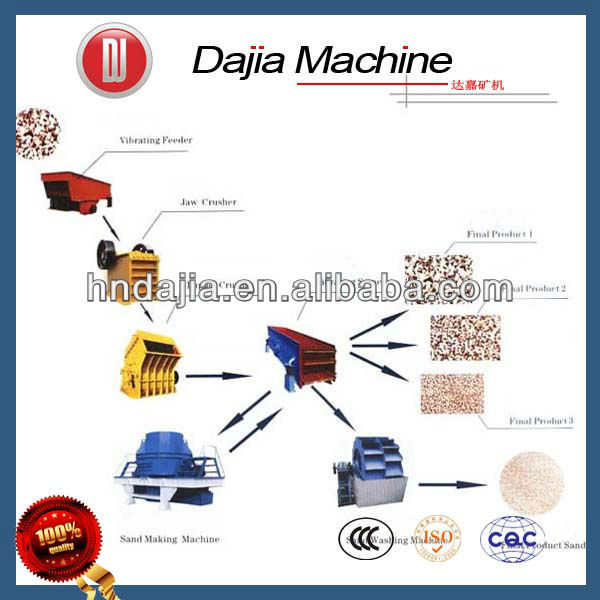

Large stone is transported to jaw crusher via vibrating feeder for primary crushing. Then crushed material is transported to sand making machine. Then the stones are screened out into several different types with a vibrating screen. Stone with satisfied size is transported to sand washing machine, then it will be final product, while overlarge stone is returned back to sand making machine for recrushing.

Application of Artificial Quartz Stone Production Line:

Stone production line is a kind of special equipment which produced the building with sands and stones. It is more energy-saving 50 to 60 percent than traditional pressure-blasting machine. Sand production line is widely used in stone factory, mine, metallurgy, building materials, highway, railway, water conservancy and chemical department. Production capacity change from 50 - to 500t/h, finished granularity needs combination and grading according to the customers' different demands.

Process of the Production Line:

The stone making processing:

Feeding material bin--- vibrating feeder-- jaw crusher—impact crusher(optional)-- vibrating screen—sand washing machine—finished stone, all machinery to be connected by belt conveyor or the sliding chute

The artificial sand making processing:

Feeding material bin--- vibrating feeder-- jaw crusher—impact crusher(optional)-- vibrating screen—sand washing machine—finished sand, all machinery to be connected by belt conveyor or the sliding chute

But the sand and stone producing line is much complex than the above 2 lines. It is as follow:

The sand and stone making processing:

1. Feeding material bin---vibrating feeder--jaw crusher--impact crusher(optional)-- vibrating screen--finished stone

2. Impact crusher-- vibrating screen--sand washing machine----finished sand, hereinto, the vibrating screen can share using, also can separately use. machinery to be connected by belt conveyor or the sliding chute

Technical Details of Artificial Quartz Stone Production Line :

| Serial number | Max. feeding size (mm) | Crushing capacity (t/h) | Models, specifications and quantities | |||||

| Feeding equipment | Coarse crushing equipment | Fine crushing equipment | Classifying and screening equipment | Belt conveyor (m) | Installed power (kw) | |||

| 1 | 300 | 30 | GZD2511(3kw) | PE400×600(30kw) | PF1007(45kw) | 3YZ1236 (15kw) | 60-90(20kw) | 120 |

| 2 | 340 | 50 | GZD3117(10kw) | PE400×600(30kw) | PF1007(45kw) | 3YZ1545(22kw) | 100-130(30kw) | 140 |

| 3 | 420 | 80 | GZD3617(10kw) | PE500×750(55kw) | PF1010(75kw) | 3YZ1548(22kw) | 130-160(30kw) | 200 |

| 4 | 480 | 100 | GZD4321(13kw) | PE600×900(75kw) | PF1210(130kw) | 3YZ1548(22kw) | 140-180(40kw) | 280 |

| 5 | 560 | 150 | GZD4321(13kw) | PE750×1060(90kw) | PF1210(130kw) | 3YZ1845(22kw) | 200-240(50kw) | 300 |

| 6 | 630 | 200 | GZD4321(13kw) | PE900×1060(110kw) | PFB1212(140kw) | 3YZ2050(30kw) | 200(40kw) | 350 |

| 7 | 630 | 250 | GZD5027(17kw) | PE900×1060(110kw) | PFB1214(180kw) | 3YZ2050(30kw) | 200(40kw) | 400 |

| 8 | 630 | 300 | GZD5027(17kw) | PE900×1200(110kw) | PFB1214(180kw) | 3YZ2160(30kw) | 250(50kw) | 450 |

| 9 | 700 | 350 | GZD5027(17kw) | PE1000×1200(132kw) | PFB1315(250kw) | 3YZ2160(30kw) | 250(50kw) | 500 |

| 10 | 700 | 450 | GZD6223(28kw) | PE1000×1200(132kw) | PFB1214/2(300kw) | 3YZ2145/2(60kw) | 350(60kw) | 600 |

Process of Artificial Quartz Stone Production Line:

Construction Site of Artificial Quartz Stone Production Line:

Company Workshop:

Company Honors and Certificates:

For further information,pls feel free to contact us .

Welcome to our factory in China.

| Packaging Detail:Standard containers,spare parts packed in wooden box. |

| Delivery Detail:30 Days |