AR6040 Automatic Hard Case Making Machine

| Condition:New | Automatic Grade:Automatic | Usage:Other Forming Machine | Place of Origin:Zhejiang China (Mainland) |

| Brand Name:Xuteng | Model Number:AR6040 | Voltage:380v 3phase | Power(W):6kw |

| Dimension(L*W*H):6.6m*4.1m*3.3m(L*W*H) | Weight:6800kg | Certification:CE | Warranty:one year |

| After-sales Service Provided:Engineers available to service machinery overseas |

AR6040 Automatic Hard Case Making Machine

Product introduction:

AR6040 Automatic Hard Case Making Machine is the best equipment to making high-grade rigid box. For example: luxury boxes, luxury packaging, gift boxes, wine and spirit boxes, shirt and shoes boxes, make-up and toiletry boxes, biscuits and cakes boxes, ring binder boxes, CD, DVD and book boxes, Underwear Boxes, Food Boxes, Hardware Boxes, Jewelry Boxes, Mobile phone Boxes, Moon Cake Boxes, Tea Boxes, Electric Product Packaging Boxes and other high-grade Rigid set-up Boxes.

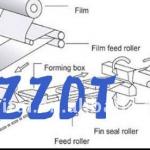

AR6040 Automatic Hard Case Making Machine adopts PLC process control, photoelectric follow-up System, Touch screen man-machine interface, Hydraulic corrective system to control location. The working process is full automatic,it can finish all workings one time, including automatically feed paperwrap and cardboard, Applying glue on the paperwrap, gluing and forming four angles of cardboard, Laminating paperwrap and cardboard, Covering edge, the box will be formed lastly. The production efficiency will be improved more than 30 times than making box by manually. It will save the cost.

MainFeatures:

- Feeding Paper Automatically.

- Gluing System is hot melt glue, which is circle and mixing automatically

- Electric hot melt cutting device finish the gluing four angle of cardboard one time, forming inner box.

- Servo Motor and Vacuum to absorb the inner box, Hydraulic corrective system is controlling location laminating of cardboard inner box and paperwrap with hot melt glue.

- Computer control conveyor to take formed inner box on paperwrap with glue automatically.

- The part of forming box will finish a series working, including feeding box, covering edge, folding flaps, lastly the box is forming.

- AR6040 Automatic Hard Case Making Machine adopts PLC process control, photoelectric follow-up System, Touch screen man-machine interface, the box is forming one time, The working process is full automatic,

- Mechanical arm of taking box adopts Guide rail and slide block model, wear-resisting and high stable.

- Fault Display, breakdown stopping automatically.

Technical parameters

Finished box size (L*W*H) | Max length | 600mm | |

Max width | 400mm | ||

Max height | 150mm | ||

Min length | 100mm | ||

Min width | 50mm | ||

Min height | 15mm | ||

Paperwrap size(L*W) | Max length | 850mm | |

Max width | 610mm | ||

Min length | 250mm | ||

Min width | 120mm | ||

paperwrap thickness | 100-200g/m2 | ||

Cardboard thickness | 0.8-3mm | ||

Paper Edge fold size | Max:35mm; min:7mm | ||

max working speed | 35 box/min | ||

laminating precision | ±0.5mm | ||

Motor power | 10.35kw/380v 3phase | ||

heater powder | 6kw | ||

Air supply | 10L/min 0.6Mpa | ||

machine weight | 6800kg | ||

overall dimension | 6.6m*4.1m*3.3m(L*W*H) | ||

Remark:

The max working speed is 35 box/min. but the box size will affect the working speed.

The max and min size of box is depending on the max and min size of paperwrap, the quality of paperwrap at the same time.

We don’t offer the air compressor, which is ready by the customer.

| Packaging Detail:one container |

| Delivery Detail:30days |