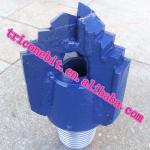

API Kingdream pdc diamond bit for water well drilling/oilfield drilling(Matrix Body)

| Place of Origin:Hebei China (Mainland) | Brand Name:Kingdream | Model Number:PDC bit | Type:Drill Bit |

| Machine Type:Drilling Equipment | Certification:API,API&ISO | Material:Carbide | Processing Type:Forging |

| Use:Well Drilling | colour:bule,red,green or as you demand | size:7 1/2 | brand:KINGDREAM,CS,Lilin,Deris |

| Formation:soft to hard formation | Warranty:4 years | Bit type:Matrix body PDC bit | IADC CODE:M223 |

| Blades:3-8 wings |

API Kingdream pdc diamond bit for water well drilling/oilfield drilling(Matrix Body)

PDC bit specifications

APICONN.(in):2 3/8 2 7/8 4-1/2,6-5/8,7-5/8

Cutter Size:1308MM,1613MM,1616MM,1619MM,1919MM

IADC:M123/122

IADC:M223/243/232

IADC:M323/333/343/332

IADC:M423

IADC:M841

IADC:S223,323(Steel body)

| Size | Number of Blades | Cutter Size | API Conn |

| 5 1/2” | 3 Blade | 13mm | 2 7/8” API REG |

| 5 5/8” | Flat Face | 13mm | 2 7/8” API REG |

| 5 5/8” | 3 Blade | 13mm | 2 7/8” API REG |

| 5 5/8” | 3 Blade | 13mm | 3 1/2” API REG |

| 5 7/8” | Flat Face | 13mm | 3 1/2” API REG |

| 5 7/8” | 5 Blade | 13mm | 3 1/2” API REG |

| 6” | 5 Blade | 13mm | 3 1/2” API REG |

| 6 1/8” | 5 Blade | 13mm | 3 1/2” API REG |

| 6 1/4” | 5 Blade | 13mm | 3 1/2” API REG |

| 6 1/2” | 5 Blade | 13mm | 3 1/2” API REG |

| 6 3/4” | 5 Blade | 13mm | 3 1/2” API REG |

| 7 7/8” | 5 Blade | 13mm/16mm | 4 1/2” API REG |

| 7 7/8” | 6 Blade | 13mm/16mm | 4 1/2” API REG |

| 8 1/2” | 5 Blade | 13mm/16mm | 4 1/2” API REG |

| 8 1/2” | 6 Blade | 13mm/16mm | 4 1/2” API REG |

| 8 3/4” | 5 Blade | 13mm/16mm | 4 1/2” API REG |

| 8 3/4” | 6 Blade | 13mm/16mm | 4 1/2” API REG |

| 9 7/8” | 6 Blade | 16mm | 6 5/8” API REG |

| 11” | 6 Blade | 16mm | 6 5/8” API REG |

| 12 1/4” | 6 Blade | 16mm | 6 5/8” API REG |

Advantage

1.Suit for drilling medium hard to hard formations.

2.Evolute asymmetrical blade cutter design and balanced bit load so that bit whirl

is prevented .

3.Composite gage protection and low torque design improve rate of penetration .

4.CFD hydraulic balance design results in better bit cleaning and cutting removal .

5.Combined utilization of high performance PDC compacts significantly prolongs

bit life .

6.Improved bit durability and directional responsiveness.

Features

1.Multiple types of high performance PDC cutters are strategically arranged on the

bit for improved service life of the bit.

2. Cutting structure is force balanced,bit bladeis asymmetrically designed, and spiral blade and spiral gage are also designed so that the load on bit is balanced that resulting better stability of the bit.

3. Optimally designed bit profile for drilling soft to medium hard formations.

4. Hydraulic system of the bit is optimized usingCFD technologyto enhance cleaning and cooling effects of the bit as well as the ability to effectively prevent bit from balling.

5.Erosion on bit surface is effectively prevented by utilizinghardfacing materialof highly erosion resistant and applying advanced base metal enhancement technology.

6. Ports on bit are also optimally designed to prevent erosion of water courses inside the bit.

7. Up-reaming features are also designed to make the bit more suitable for various drilling processes.

Products show

| Packaging Detail:plywood box or steel box or according to your requirement |

| Delivery Detail:3 business days after receiving the deposit |