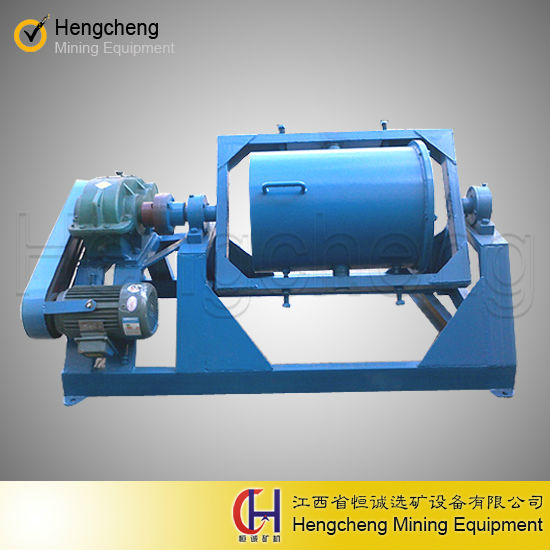

Amalgamator for Gold Refining, Gold Refine Machine

| Place of Origin:Jiangxi China (Mainland) | Brand Name:Hengcheng | Model Number:Light & Heavy type | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | Type:internal amalgamating equipment | Application:gold cleaning concentration, gold refine | Usage:gold recovery |

| Color:as per customer's rquest | Warranty:1 year | After sale service:whole life time | Certification:ISO9001-2000 |

| Reagents:mercury | Motor power:2.2-2.5kw | Volumn:0.233-0.6m³ |

Amalgamator for Gold Refining, Gold Refine Machine

Description

Amalgamation cylinder, as a type of internal amalgamating equipment that is widely used in gold processing plant, is used to process heavy sand containing gold of gravel mine and gold concentrate of vein gold mine, presenting a gold recovery rate of higher than 98%.

Amalgamation cylinder is used to recover the gold from ore concentrate, heavy sand and various ores.

Although most of the gold in gold concentrate is in free form, the surfaces of gold grains are usually polluted to a greater or less extent, and some gold exists with other minerals or vein rocks in adherent form. . When gold concentrate is processed with amalgamation cylinder, steel balls are usually added to the cylinder for grinding operation to remove the film on gold grain surfaces and separate the gold grains from adherent bodies.

When the heavy sand ore concentrate of free gold grains with clear surfaces is treated, we usually use light-duty amalgamation cylinder with extremely small quantity of steel balls. . When processing the heavy sand ore concentrate with high adherent body content and serious gold grain surface contamination, we usually use heavy duty amalgamation cylinder, for which 1-2 kg of steel balls need to be loaded for 1kg of heavy sand ore concentrate. . The loading quantity of concentrate and steel balls of amalgamation cylinder is related to material grain size and gold content.

During non-alkaline medium amalgamation, heavy sand ore concentrate may produce magnetic mercury amalgam due to the interfusion of Fe substances. . Hence, internal amalgamation is usually operated in alkaline mediums. The quantity of lime is 2%-4% of loading capacity, and water quantity is usually 30%-40% of loading capacity; alternatively, the usual grinding concentration can also be used.

Technical Specification

Type | Inner Size | OreLoading (kg) | Speed (r/min) | Power (kw) | Ball Weight (kg) | Ball Dia (mm) | |||

| Dia | Length (mm) | Volumn (m3) | |||||||

Light Type | 420 | 600 | about 0.3 | 50-90 | 20-22 | 0.75-1.5 | 10-20 | 38-50 | |

Heavy Type | 0-31 | 600 | 800 | 0.233 | 100-150 | 22-38 | 0.3-2.1 | 150-300 | 38-50 |

0-3b | 750 | 900 | 0.395 | 200-300 | 21-36 | 1.7-3.75 | 300-600 | 38-50 | |

| 800 | 1200 | 0.60 | 300-450 | 20-33 | 3-6 | 500-1000 | 38-50 | ||

Laboratory Amalgamator

| Packaging Detail:exporting standard packing, Amalgamator for Gold Refining/Refine Machine |

| Delivery Detail:30 days |