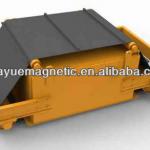

Amalgamating Equipment for Gold Recovey

| Condition:New | Type:Gravity Separator | Production Capacity:98% | Place of Origin:Shandong China (Mainland) |

| Brand Name:mercury amalgamator for gold refining | Model Number:HA3293 | Voltage:110-380v | Power(W):18.5 |

| Dimension(L*W*H):2500*2000*2400mm | Weight:2800kg | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas |

| Engine:50kw Diesel Engine |

Mercury Amalgamation

The pattern of Hg use varies widely both over time and among regions. Before the end of the 16th century, limited amounts of metallic Hg were used in alchemy and in applying gold amalgam to surfaces to be gold-plated (gilding), where after Hg was evaporated by heating. Silver amalgam was later used in the same way to make mirrors from glass sheets. The "discovery" of the new world lead to a drastically increased production of metallic Hg, which was mainly used for the extraction by amalgamation of silver in Latin America and later for gold in North America. This was the dominating use of Hg for more than three centuries. (reference)

The production of silver in South America increased significantly after 1555, when the Hg amalgamation process was introduced. This drastically reduced the use of firewood, which had become scarce around the mines, and made silver extraction profitable also in the abundant silver ores with a metal content lower than the ores worked in Europe. Interestingly, mainly smelting techniques were employed for silver mining in Sweden and the rest of Europe, while amalgamation with mainly European Hg was performed in the Americas.

With the shipment of Hg from Aomadrn in Spain and also from Idrija in Slovenia for use in silver mining in central and south America, about 130 000 t of Hg were sent overseas until the end of the 19th century. In addition, more than 50 000 t of Hg was produced in the Huancavelica mines in Peru. The amount of Hg originating from Spain and Peru and consumed by Spanish-American silver miners between 1570 and 1820 was estimated to be 114 215 t Hg. Also after independence, silver was mainly produced with the amalgamation method in Spanish America for the rest of the 19th century. The fate of this Hg is at debate.

Mercury used for silver and gold mining in the Americas is about half of all primary Hg historically mined. The more than a century-long time period, which has passed since historic amalgamation peaked, is a short period in geological perspectives. The fate of soil Hg bound to soil organic matter, metal oxy-hydroxides, and other soil compounds binding Hg deposited on land, is poorly known, but the influence of historic emissions is likely to last for centuries. In the temperate, boreal forest zone, Hg deposited binds initially mainly to organic matter and is mainly released when the organic matter is mobilized or mineralized. The half life for soil organic matter of the organic horizon of boreal forests is typically several decades or centuries, depending among other on climatic conditions. Further, the turnover time of organic matter varies by orders of magnitude between different fractions and thus depends on composition and heterogeneity.

This is expected to result in a long and variable time-lag on the order of centuries between changes in anthropogenic Hg emissions and corresponding responses in Hg concentrations of fish and wildlife.

Although gold deposits were discovered in North America already in 1799 in North Carolina, it was the discovery of gold in California in1847 that initiated the gold rushes in North America, culminating half a century later in Klondike in western Canada and in Alaska, which during its peak consumed about half of the global Hg production at that time. The resulting dispersal of Hg to the environment is still evident, manifested by elevated Hg contents in soils, sediments, and fish downstream historic gold mining sites, leading to restrictions on fish consumption. Most of the 63 300 t of Hg mined in the USA and Canada between 1850 and 1900 was used for gold mining in North America and Australia. Cyanide leaching was introduced around 1880 and became widely used a few years after the turn of the century, but a significant use of Hg in gold mining continued for another decade, which is also evident from lake sediment profiles.

An increased gold price during the 1980's boosted a new gold mining boom using Hg for amalgamation. This time the boom took place in Latin America, Central Africa, and South East Asia. An estimated 2 000 t of Hg have been dispersed in the Amazon alone during this latest gold rush, which still continues although at reduced scale in the Brazilian Amazon, due to exhausted placer deposits. As a consequence, many Brazilian gold miners are nowadays working gold deposits with the amalgamation technique in neighboring countries. Large but not quantified amounts of Hg have also been used for gold extraction in China, Mongolia, and Russia (mainly Siberia) using Hg from local mines. Amalgamation is officially banned in China since 1985 and in Russia since 1990.

In spite of the bans, Hg consumption for gold amalgamation in China was estimated to 80 t in 1995, of which up to 75% may have been recycled. Sukhenko and Vasiliev report 30 t of annual Hg emissions from amalgamation in Siberia in the beginning of the 1990's. Consumption and emissions of Hg in southeast Asia during the last goldrush is poorly quantified. According to Appleton et al., an estimated 140 t of Hg was released into the Agusan River catchment in the Philippines during the period 1986-1988 when gold mining peaked there, while there are no figures for the years before and after this period or for other parts of the Philippines or neighboring countries, where the amalgamation technique is known to be used. On going efforts within the United Nations Environment Programme, the United Nations Industrial Development Organisation, and the World Bank is expected to contribute with updated quantification of the present Hg use for gold extraction globally.

Mercury used for gold mining in Africa was addressed when Communities and Small-Scale Mining (CASM) held their third annual general meeting and learning event in Ghana, 2003. The participants expressed preoccupation about the large quantities of Hg emitted by small-scale gold miners with associated damages to both human and environmental health. Annually, an estimated 500-700 t of Hg is emitted by small-scale miners, of which at least 10% is emitted in Africa, a region poorly recognized regarding Hg usage in small-scale mining.

Globally, 10 to 15 millions small-scale gold miners are active, most of them using Hg. Retorts have at some places been introduced to reduce Hg emissions and thereby the health hazards for the miners, but results show that the use of retorts has not reduced the emissions of Hg to an acceptable level at the mining sites. There are an increasing number of alternative, Hg free methods on the market, being viable alternatives to continued use of Hg. However, these efforts are counteracted by the agreement between the European chloral-alkali industry and MAYASA (the company owning Hg mines in Almaden, Spain) to transfer excess Hg to Spain for reselling on the world market.

It should be noted that tailings from the amalgamation technique in some cases are submitted to cyanide leaching to recover remaining gold, thereby aggravating the environmental emissions of Hg.

| Packaging Detail:Container for mercury amalgamator for gold refining |

| Delivery Detail:15 days after relevant payment |