Aluminum thermal barrier potting machine

| Place of Origin:China (Mainland) | Brand Name:LIANSHI | After-sales Service Provided:Overseas service center available |

Huagong Innovation Technology (Dalian) Co.Ltd. is an industrial company mainly with research and development,

manufacturing and marketing. Our main products are: Pouring insulated aluminum special polyurethane pouring

system, including potting machine, bridge cut-off machine, knurling machine and two-color laminating machine.

Automatic 3D spreadingmachine, wide board twocomponent automatic spreading machine; Germany BASF polyurethane

insulation glue etc.

The company is located in the beautiful coastal cityDalian. We have a highly qualified scientific and management team,

Since November 2001 our company developed the first Lianshi brand pouring and bridge cut-off combination machine,

we have alternative products instead of imported equipments. wide-area sales network, perfect system technical

support and attentive after-sales service system bring customers real peace of mind.

Our products not only occupy a certain market in China, but also a large part is sold to North America, Europe, Africa,

Asia and other countries and regions.

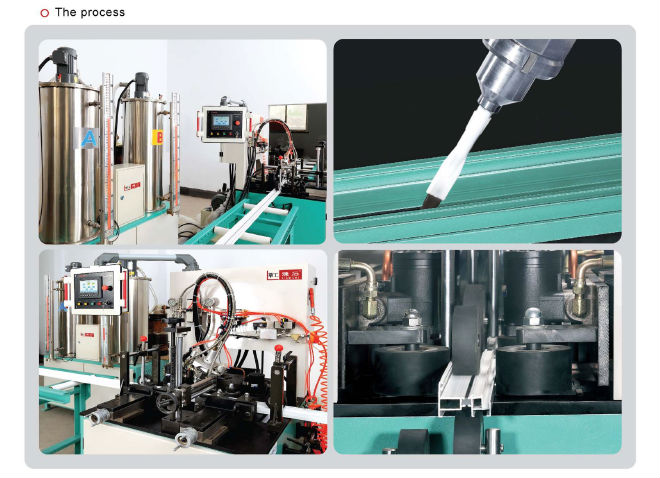

Aluminum thermal barrier potting system is decided to processing PU potting thermal insulating into aluminum

profiles.Mainly used for the injecting type heat insulation sectional materials for building energey conservation

doors and windows. It contains knurling machine,potting machine, bridge cut-off machine and two-color laminating machine.Polyurethane casting machine is through the hydraulic system driving the aluminum

profile along the specified direction of smooth and uniform movement,And then through the precise measurement

system making A,B components heat insulation adhesive, through an instant high-speed mixing, and

in accordance with the provisions of the ratio and flow injection into groove, completed the casting process.

This system is in a leading position in China, with advantages of high efficiency, energy saving and

environmental protection.

LIANSHI knurling machine is a patent equipment to improve adhesive properties between thermal insulating

PU and coating surface of some aluminum profiles and increase shearing force of aluminum profiles .The

equipment uses a mechanical method to make teeth at the notch of aluminum profiles by operating opening

teeth knife fast, so that chemicals contact with the aluminum part.A better physical connection is formed

Potting machine is designed for pouring thermal insulating polyurethane into aluminum profiles.It drives the

aluminum profile to go with a smooth and uniform movement system along a specified direction.Then the

precise measurement system makes A B components do an instant high speed and uniform mixing .After that

polyurethane flows into thermal insulating tank accordance with the provisions of the ratio to complete the

potting process.

LIANSHI Bridge cutoff machine is used after the pouring and curing of the aluminum profiles,with the driven of

hydraulic system .It uses a high-speed cutting tool to remove the aluminum alloy of the thermal insulating

tank bottom,then thermal insulating materials are obtained .

Ⅱ. Advantages

1. Our company specializes in the research and development of chemical equipment involveing in the field of

plastic injection for ten years, we have accumulated a lot of experience. We successfully brought the German

BASF insulation material into China, produced in our hometown and then became the exclusive agents of the

German BASF Polyurethane in China. If customers use our equipment and glue, when there is something wrong

with the device quality, there is no need to divise the responsibilities, we will solve the problem at the first time

to ensure the production.

2. After numerous tests in cooperation with the world's top 500 - BASF of Germany, we serve the customers the most reliable equipments and the most stable polyurethane

glue service, our advantage is more prominent in the field of chemical equipments,

3. For the configuration of the device, Hua gong’s configuration and imported equipment configuration are

entirely consistent (directly order the accessories from the United States), and we will improve them on the

basis of imported equipments. For bridge cut-off machine, we adopted the aluminum shavings separation system, it can decompose, recycle and reduce

energy consumption, 80% of aluminum shavings can be separated out, the value of recycling is significant.

The equipment is better than imported equipments.

4. Independent research and develop control system

5. We have a variety of types for customers to choose, to meet the different needs of customers, to provide

customers with the most economical, affordable equipment and system services.

| Packaging Detail:plastic cover in container |

| Delivery Detail:45 |