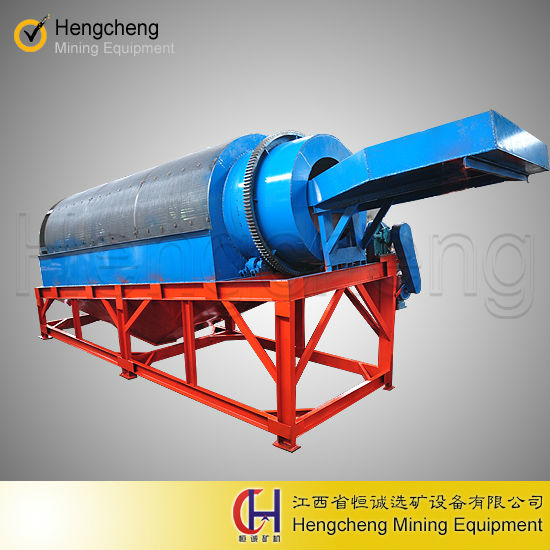

alluvial gold concentrating machinery with gold sluice box

1. Easily changed screen plates, 2. Largest processing capacity in the industry, 3. Multiple screen size - details see: https://www.machineto.com/alluvial-gold-concentrating-machinery-with-gold-sluice-box-10321415

| Condition:New | Type:Circular | Application:Ore | Place of Origin:Jiangxi China (Mainland) |

| Brand Name:HengCheng | Model Number:SZZ | Voltage:380/440 Votage | Power(W):4.0-30Kw |

| Dimension(L*W*H):3000*1400*2145 - 7500*2500*4000 | Weight:340-2100kgs,2200 - 8600 Kg | Certification:ISO9001:2000 | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas | Capacity:5000 - 40000t/h | Drum Diameter:1000 - 2000mm | Drum lenth:1500 - 5500mm |

| Screen Size:<3~10 mm | Sample tests:available | training course:available | spare parts:available |

alluvial gold concentrating machinery with gold sluice box

Description

gold ore washing plant trommel screen machine, Material feeds into the drum, is lifted up by the rotation and aerated as it falls back down. This action is repeated with each revolution along the length of the drum. The finer material passes through the screen openings while the larger material tumbles towards its eventual exit at the rear of the drum.

Features

· Configured for economical & efficient classification, Screening and grading

· Heavy duty trommel drum with lifters at the front to facilitate material break up

· Screen replaceable for different mesh sizes

· Multiple screen size

· Easily changed screen plates

· Largest processing capacity in the industry

· Unique screen design, result in higher capacities, longer screen life and no material clogging

· Heavy duty feed hopper and extension

· Discharge chute

· Gear drive mechanism

· Variable speed drive mechanism

Descriptions

The gold drum screen provides a simple, efficient and economical solution to upgrade a wide rang of material and optimize the subsequent process steps of recovery. This method of screening helps to reduce operating and investment cost and to increase product quality, while allowing rapid and large volume processing.

The gold drum screen provides a simple, efficient and economical solution to upgrade a wide rang of material and optimize the subsequent process steps of recovery. This method of screening helps to reduce operating and investment cost and to increase product quality, while allowing rapid and large volume processing.

Trommel screens are constructed of high quality material, designed for high performance, high production rates, lower operating costs and lower maintenance. This material is then passed on to the downstream process equipment which can be in various forms such as centrifugal

Concentrator, spirals, jigs etc.

Technical specification

| Model | Capacity (t/h) | Power (kw) | Drum Diameter (mm) | Drum Lenth (mm) | sieve mesh Size (mm) | Dimesion (mm) | Weight (kg) |

| GT1015 | 10 | 4.0 | 1000 | 1500 | <3~10 | 3000*1400*2145 | 2200 |

| GT1020 | 20 | 5.0 | 1000 | 2000 | 3460*1400*2145 | 2800 | |

| GT1225 | 35 | 7.5 | 1200 | 2500 | 4146*1600*2680 | 4200 | |

| GT1530 | 50 | 11 | 1200 | 3000 | 4460*1900*2820 | 5100 | |

| GT1545 | 70 | 15 | 1500 | 4500 | 5960*1900*3080 | 6000 | |

| GT1848/1850 | 90-150 | 22 | 1800 | 4800/5000 | 6500*2300*4000 | 7500 | |

| GT2055 | 120-200 | 30 | 2000 | 5500 | 7500*2500*4000 | 8600 |

More Pics for reference:

Additionally:

# We can help you with the beneficiation process design,installation,debugging, beneficiation test and any other customized service you may need.

# Welcome to visiting our factory to check all kinds of benificiation machinary.

# For more details, Please contact us at anytime. I will reply you immediately.

Skype: zack.mei

Phone: +86 13507077089

| Packaging Detail:Export Standard |

| Delivery Detail:Within 30 days |